Popis

TSR - rotating tube furnace range

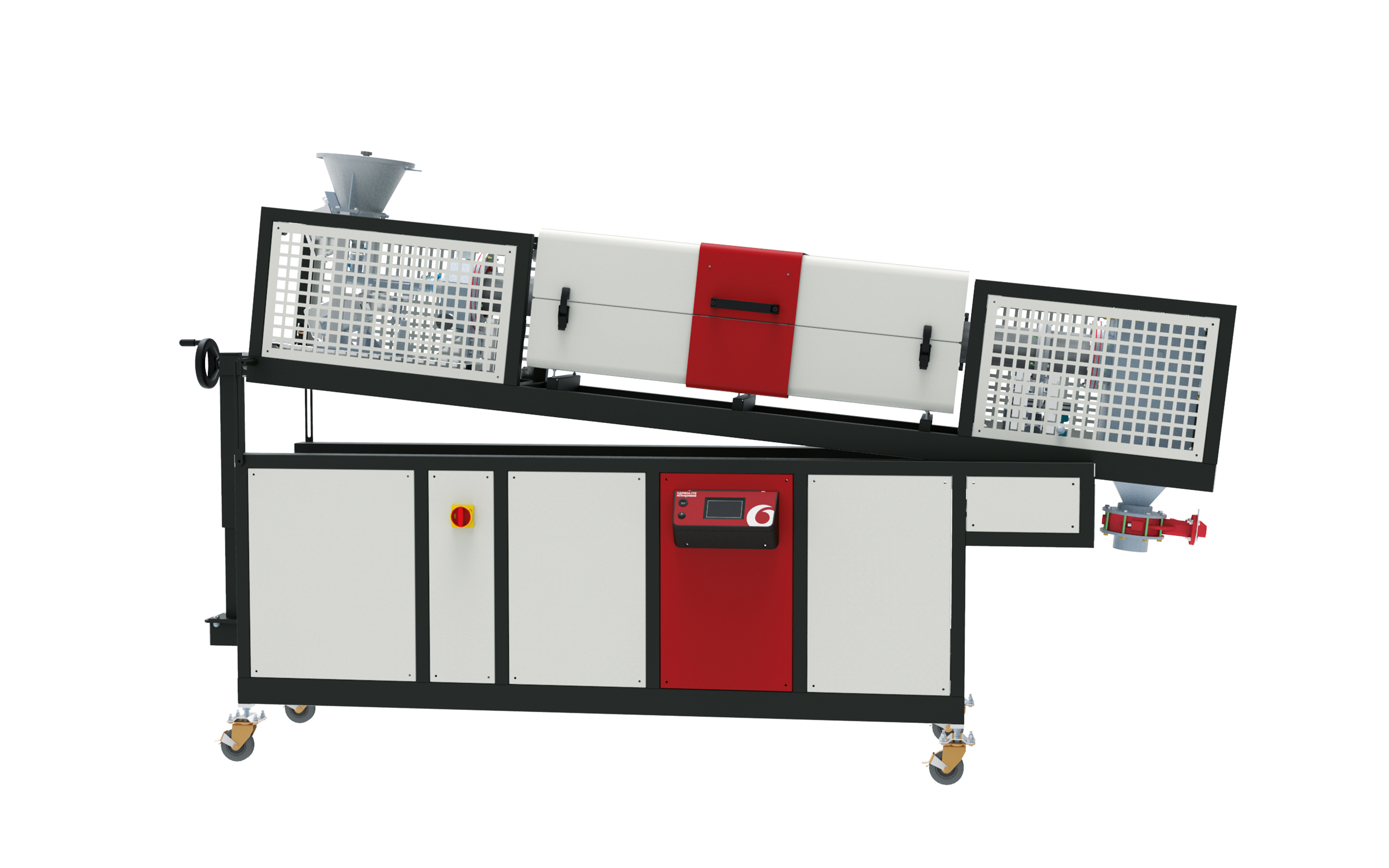

Carbolite Gero's TSR rotating tube furnace range incorporates the same innovations developed for the TS split tube furnace series with the equipment required to process large batches of free-flowing material, such as powders.

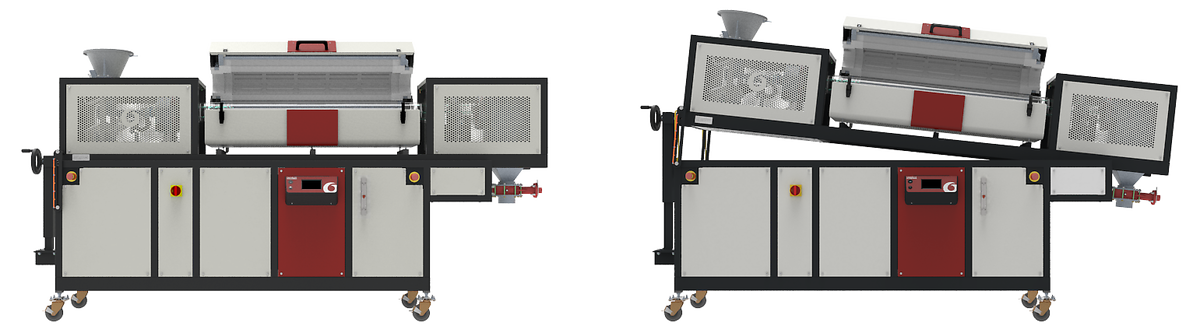

The TSR range comprises a split tube furnace horizontally mounted on a base frame, and fitted with a friction drive rotation system, allowing for work tube rotations of up to 10 rpm. The frame can be manually tilted up to a maximum angle of 6˚ to suit the requirements of the material being processed.

Accessory work tubes can easily be exchanged to meet the different physical or chemical requirements of a process.

Optional built-in gas systems enable users to equip the TSR rotating tube furnace for operation under a modified atmosphere.

PRINCIP VEDENÍ TEPLA

|

|

Nové trubkové pece Carbolite Gero jsou výsledkem více než 80 let zkušeností s v oblasti tepelného zpracování; kombinují nejnovější technologický trend, robustní konstrukcí, vysoce kvalitním komponenty a elegantním moderním designem. The rotating motion of the TSR helps increase the surface area of the sample material exposed to the atmosphere within the work tube, helping to speed up reaction times and improve the overall yield. A 5 litre capacity vibratory feeder and corresponding collection hopper makes the TSR the ideal choice for continuous heat treatment processes. VYSOCE KVALITNÍ TOPNÉ ELEMENTY

VYSOCE KVALITNÍ TEPELNÁ IZOLACE

|

REGULACE TEPLOTY A MOŽNOSTI KOMUNIKACE

|

Trubkové pece TSR jsou standardně vybaveny ethernetovou komunikací a programovatelným regulátorem s 24 segmenty:

MOŽNOSTI

|

MODIFIED ATMOSPHERE AND MATERIAL MOVEMENT

|

Standard quartz work tube and optional metallic work tube

Gas flow control by a digital flow meter

|

The Carbolite Gero TSR rotating tube furnace may be equipped with gas connections to accommodate modified atmosphere applications.

MOŽNOSTI

|

CUSTOM DESIGN OPTIONS

We have a wealth of knowledge built up over years of assisting customers with their rotating tube furnace applications. Certain applications will benefit from a selection of custom options including:

Material movement options to aid movement of the material including:

- Metallic helical work tube inserts. These are used to control the movement of material through the work tube

- Feed knockers and agitators

- Scraper bars or wires within the work tube

- Water cooled collection hopper

- Automated discharge valve

- Steam injection - digitally controlled evaporator/mixer unit with mass flow controllers for the delivery of a carrier gas (N2) and water

ANGLE OF INCLINATION

|

To assist in the flow of material through the work tube, the TSR can be tilted to a maximum of 6° using the manual winding wheel. By adjusting the angle of inclination, the operator can control the residence time of the material within the heated zone of the rotating tube furnace; the ability to change the angle ensures that the TSR has the flexibility to process many different materials with various grain sizes, from granules to powder.

|

|

TORREFACTION & BIO-COAL

|

Torrefaction is a thermochemical process carried out in the absence of oxygen to cause the partial decomposition of biomass. Water and volatiles are released from the biomass to leave a solid, dry material known as bio-coal. For some applications, bio coal can be used to replace traditional fossil fuels, thus helping to reduce CO2 emissions. |

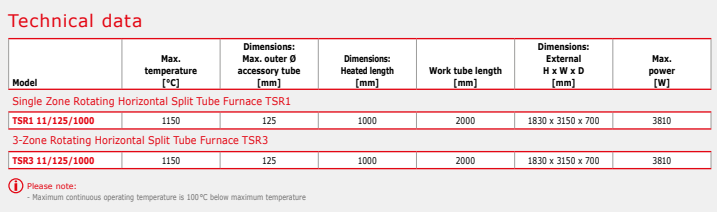

TECHNICKÉ ÚDAJE

VEZMĚTE PROSÍM NA VĚDOMÍ

|

KONFIGURACE

|

Laboratorní trubkové pece (12.1 MB)

Laboratorní trubkové pece (12.1 MB)

TSR rotating tube furnace range (486.3 kB)

TSR rotating tube furnace range (486.3 kB)

VIDEA:

OSTATNÍ VIDEA KE SHLÉDNUTÍ.....

| Hmotnost | 0.1 kg |

TSR rotating tube furnace range

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.