› Měření tvrdosti › Mikrotvrdoměry Vickers a Knoop › QNESS 10 / 60 A+ Mikrotvrdoměr

Popis

QNESS 10 / 60 A+ Mikrotvrdoměr

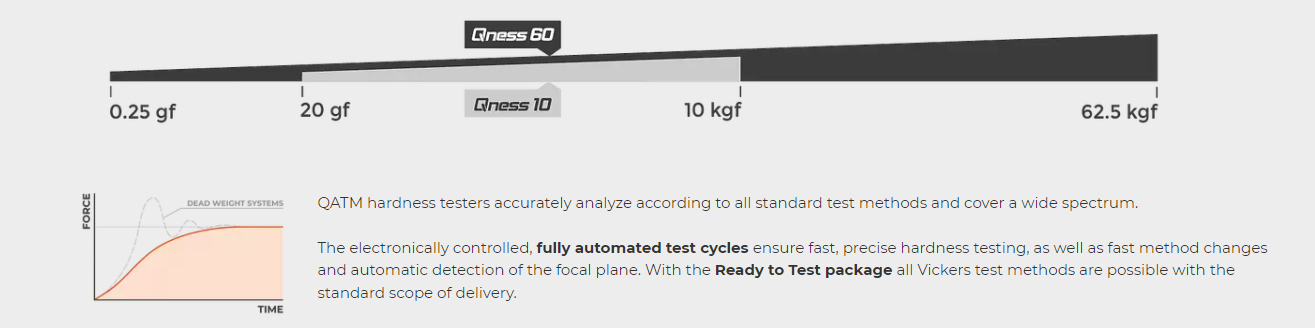

široký rozsah zkušebního zatížení 0.25 g – 62.5 kg (0.00245- 613.1 N)

Vickers / Knoop / Brinell / Rockwell

The Vickers / Knoop / Brinell / Rockwell hardness tester series Qness 10 / 60 takes micro hardness testing to a whole new level: The high-end laboratory devices of the latest generation combine the best of both worlds – hardness testing and microscopy without compromise and with maximum operating convenience. The revolutionary optical system with color camera provides reproducible and reliable results every time.

The classic „Qness 10 / 60 A+” model of this Vickers / Knoop / Brinell / Rockwell hardness tester promises perfect automation and comes with a precision positioning control for all three axis systems. Flexible XYZ progressions for thousands of analysis points allow for exceptionally high throughput without operator intervention.

QATM micro hardness testers seamlessly integrate with the Verder Scientific IoT platform, featuring remote real-time monitoring, live notifications, effortless backups and automatic software updates.

QNESS 10 / 60 A+ PRODUCT ADVANTAGES

- Wide test force range (0.25 g – 62.5 kg)

- Ready to Test package, includes: ASTM+DAkkS certified Vickers diamond and 5x / 20x / 50x lenses

- Dynamic test turret with 8-position tool changer

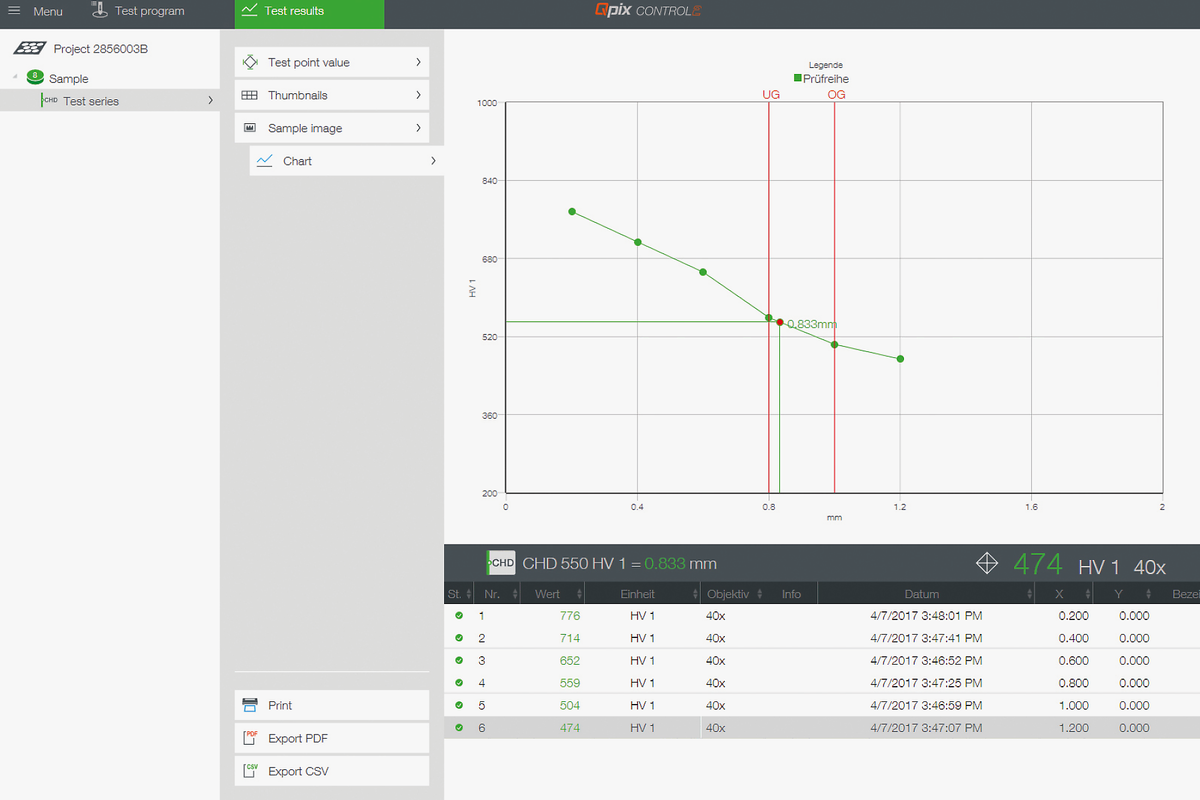

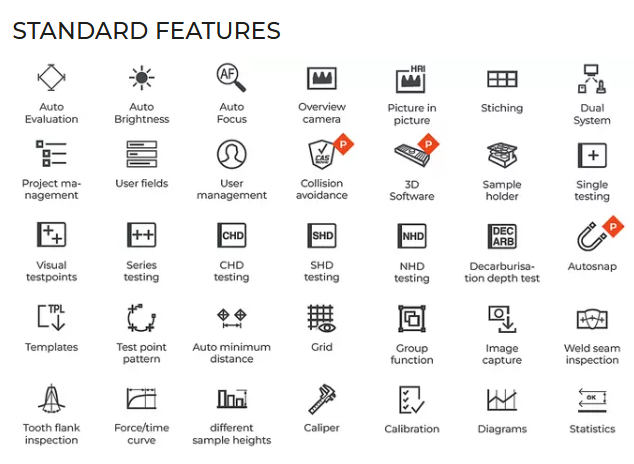

- Qpix Control2 Software with innovative 3D operation

- Modular activation of INSPECT microscopy features

- Fully automated, unmanned test and analysis cycles

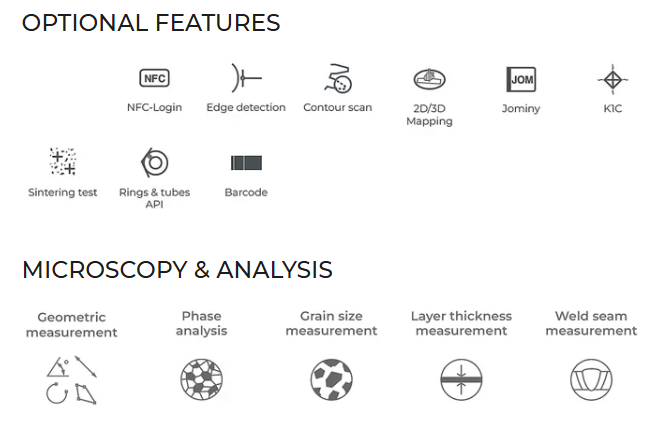

- XYZ axis control with direct optical path measuring system (table position accuracy of +/- 2 µm)

- Variant A+ only: Sample image camera with automatic image acquisition (52 x 39 mm)

QNESS 10 / 60 A+ EXPERIENCE THE 3D MODEL IN THE REAL WORLD!

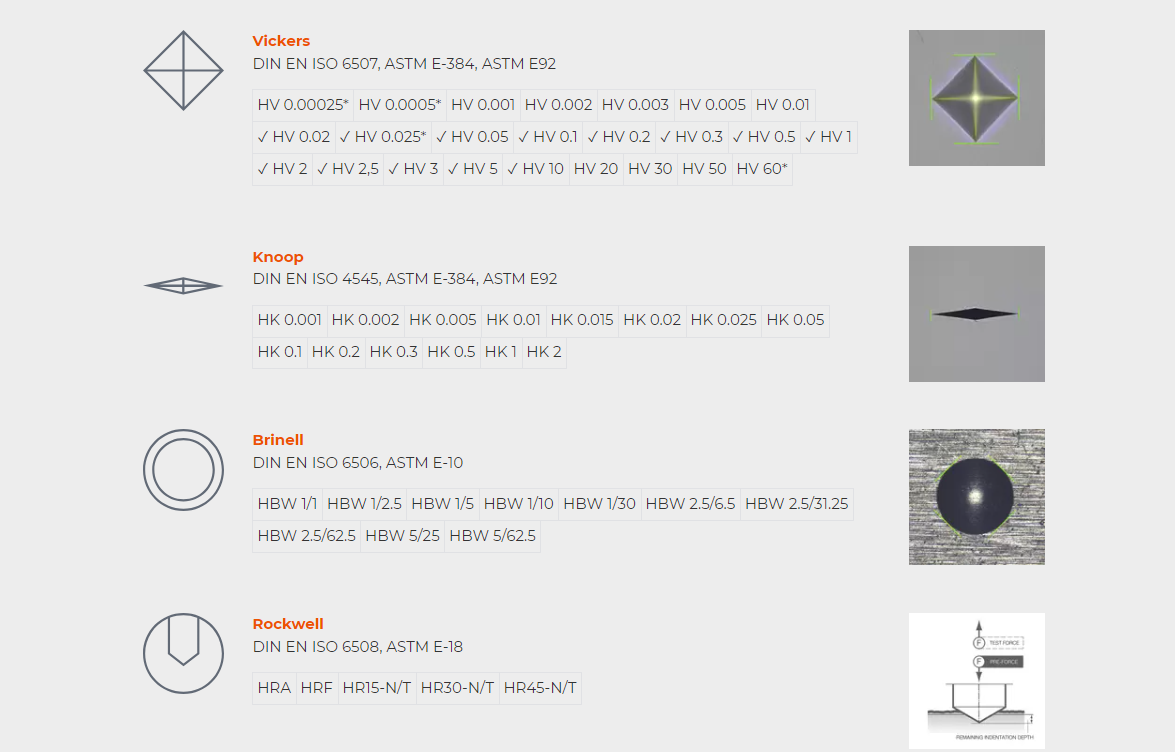

QNESS 10 / 60 A+ TEST METHODS & FORCE RANGE

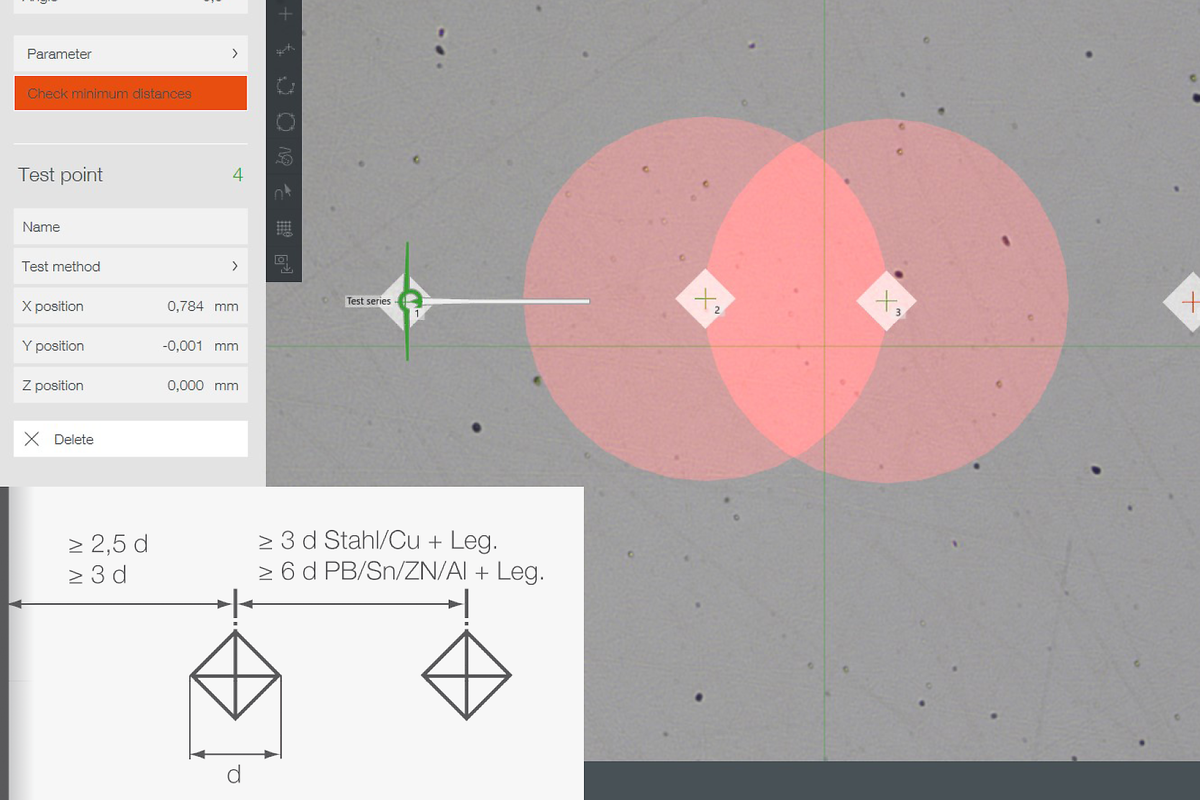

QNESS 10 / 60 A+ MICROSCOPY & ANALYSIS WITH QPIX INSPECT

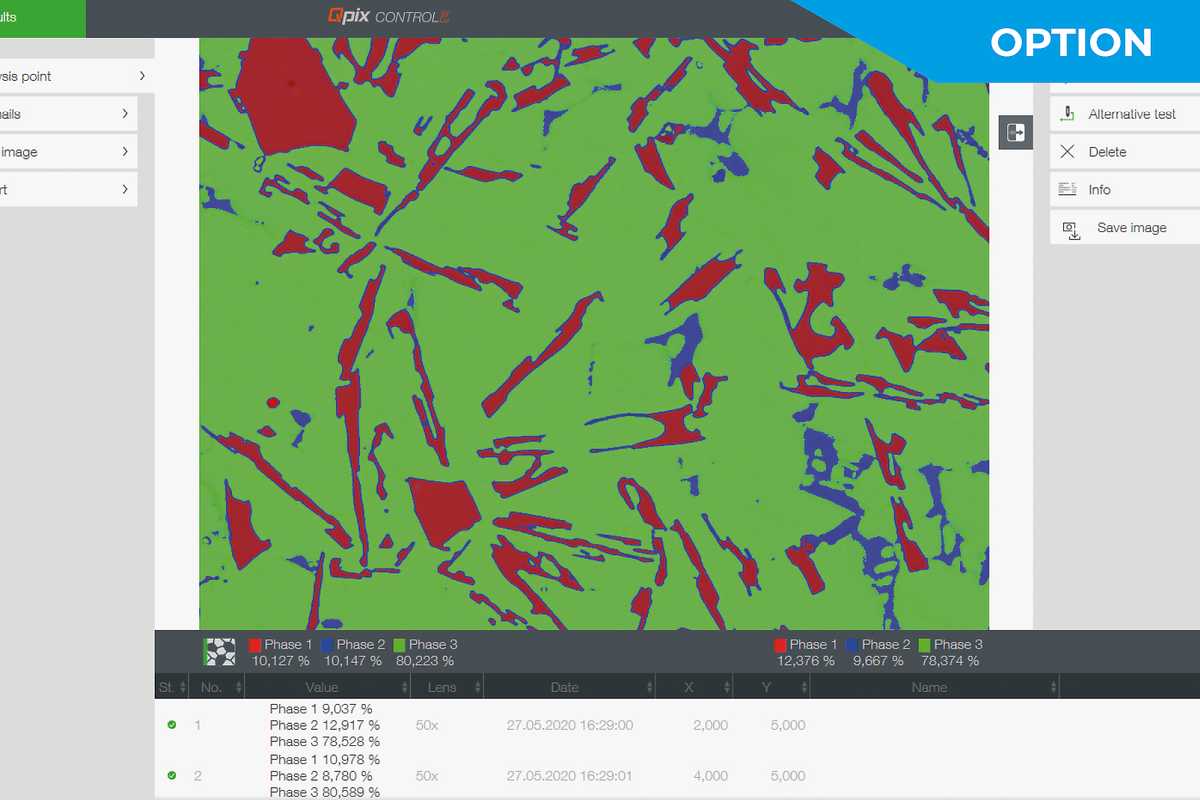

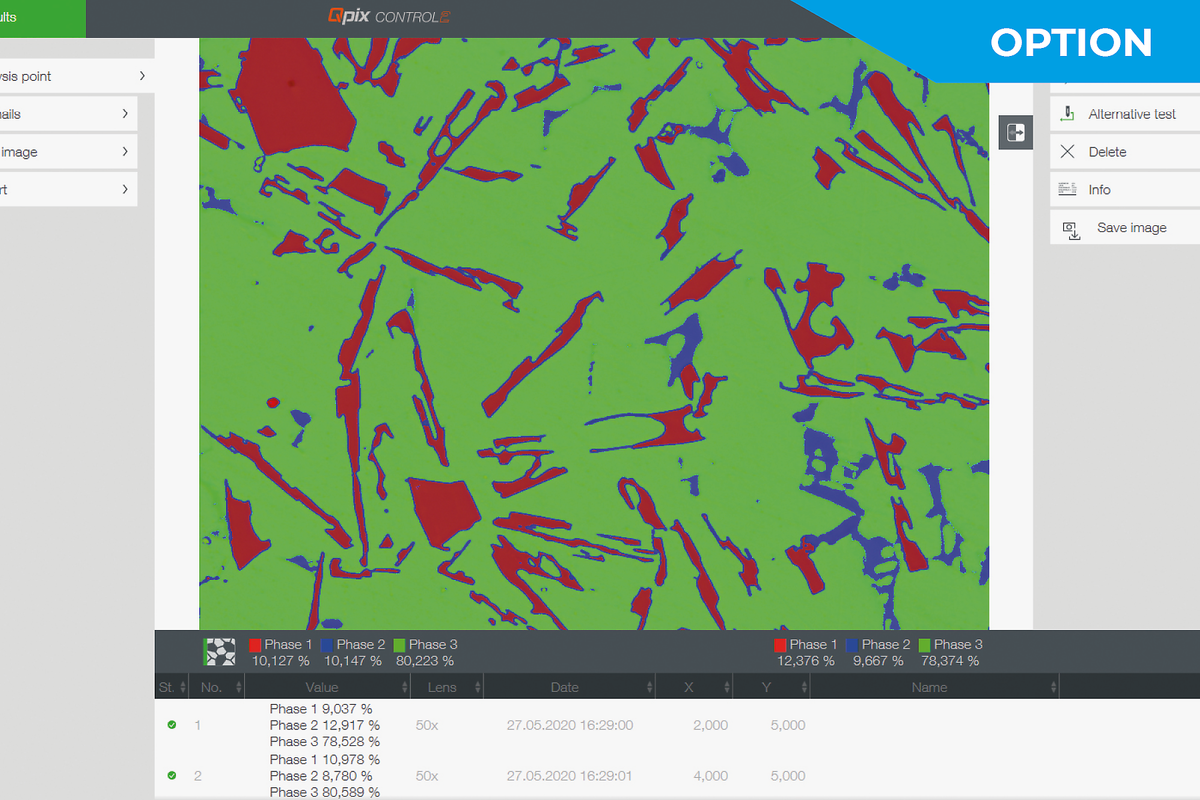

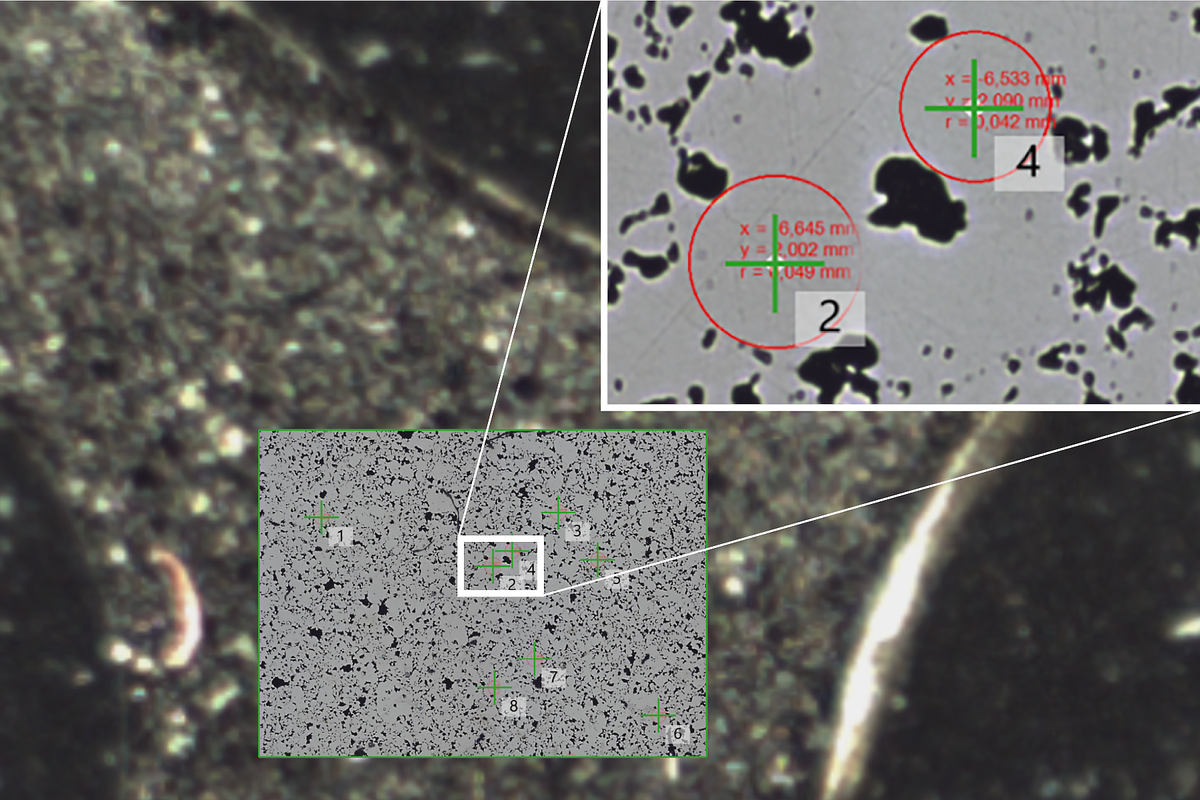

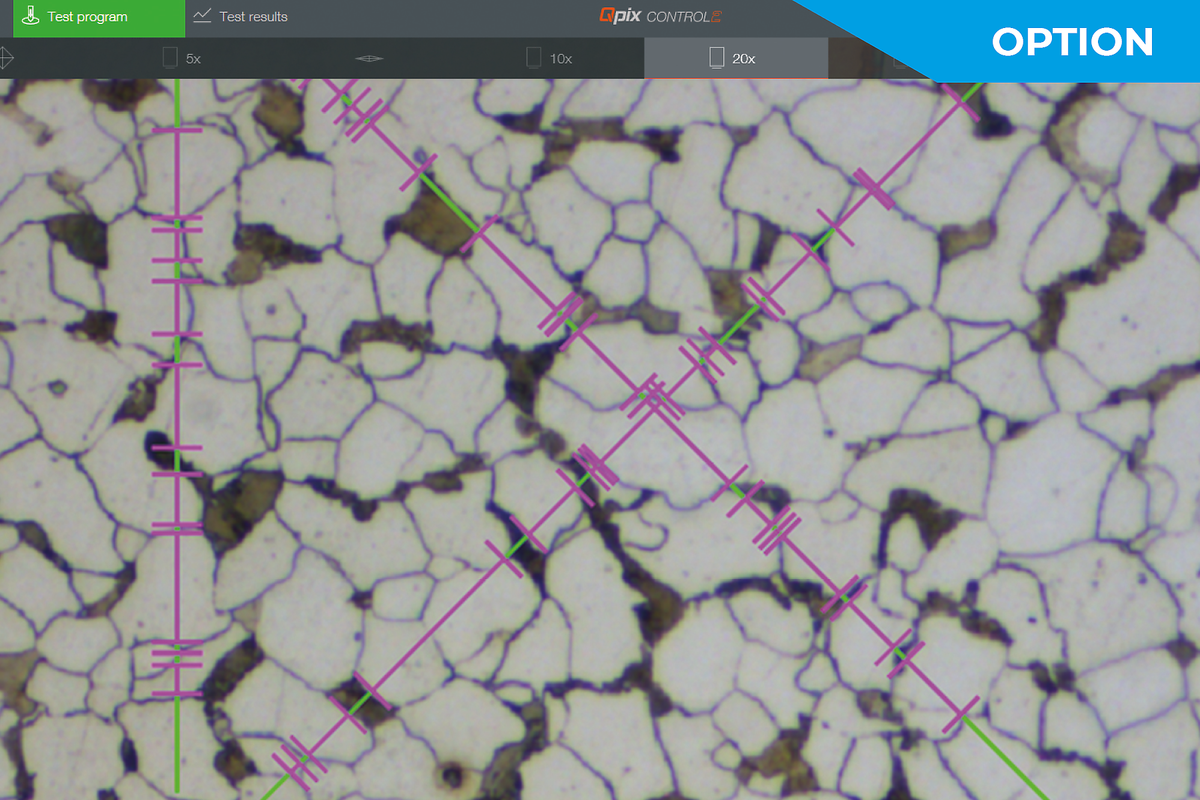

PHASE ANALYSIS

DIN 9042, ASTM E-562

Automatic image object dimensioning Provides analysis results as percentage proportions of a surface or as nominal surface values as tables or diagrams

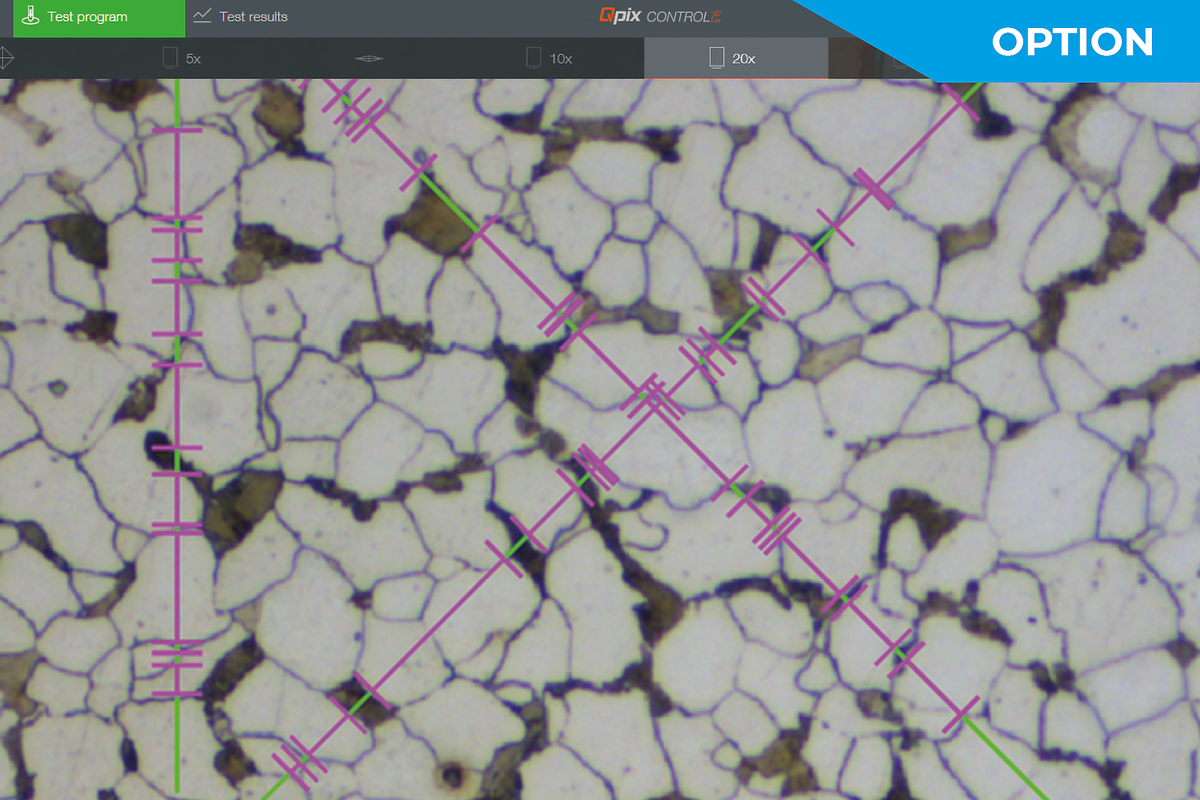

PARTICLE SIZE DETERMINATION

DIN 9042, ASTM E-562

Particle size determined via linear or circular section method Results of the analysis provided as tables or diagrams Abrams Circles, Heyn Lines, Snyder-Graff Line

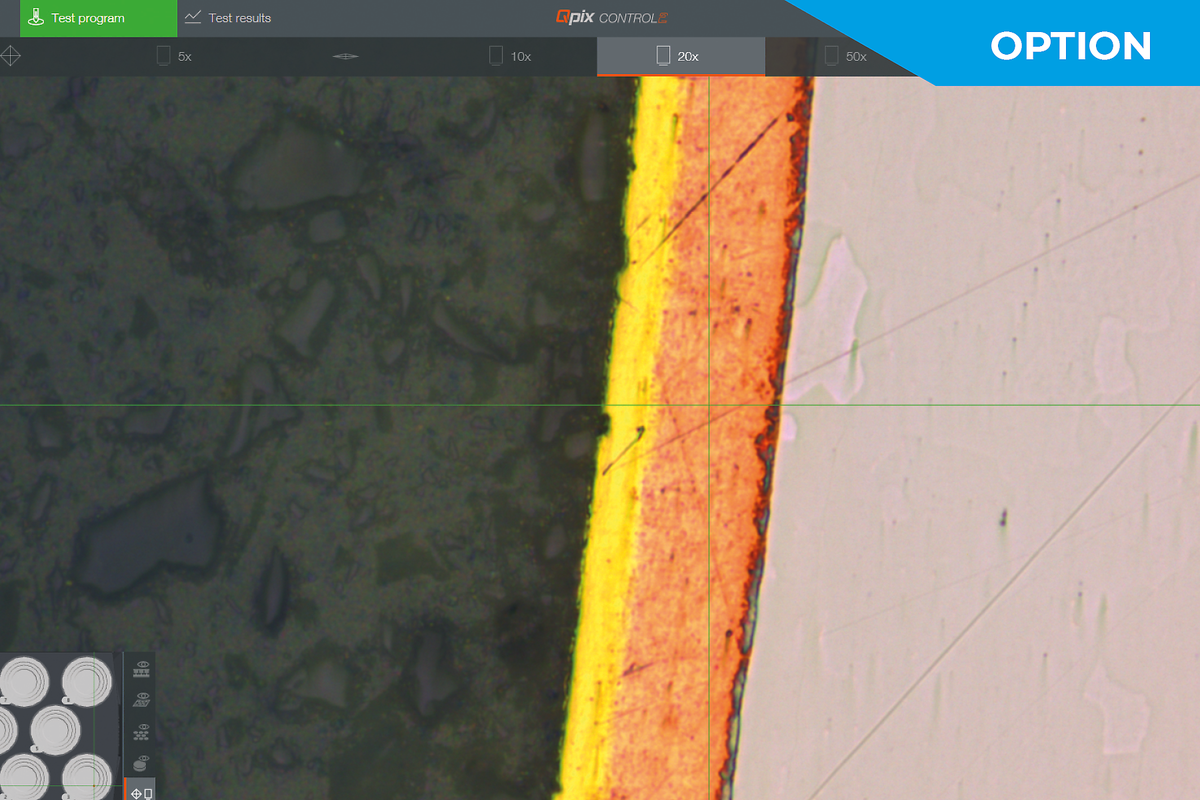

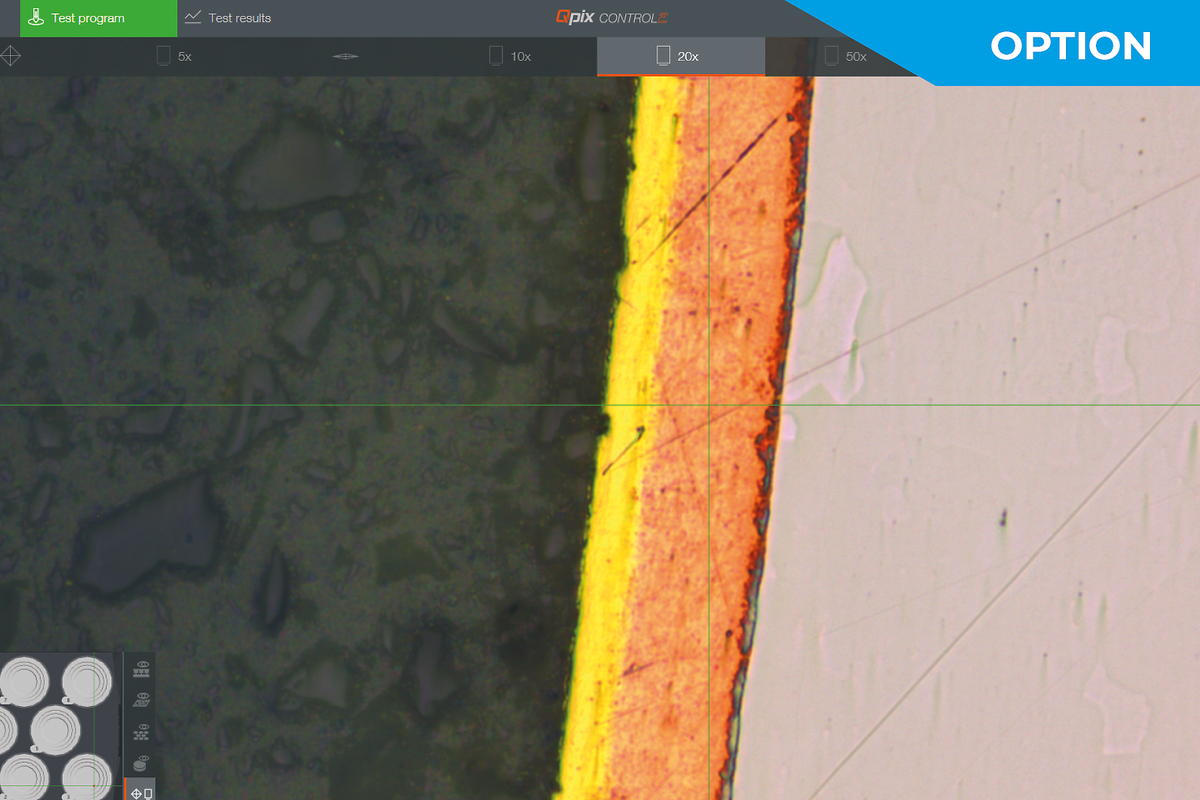

LAYER THICKNESS MEASUREMENT

DIN EN ISO 1463

Determination of layer thickness Semi-automated gauging of horizontal, vertical and radial layers.

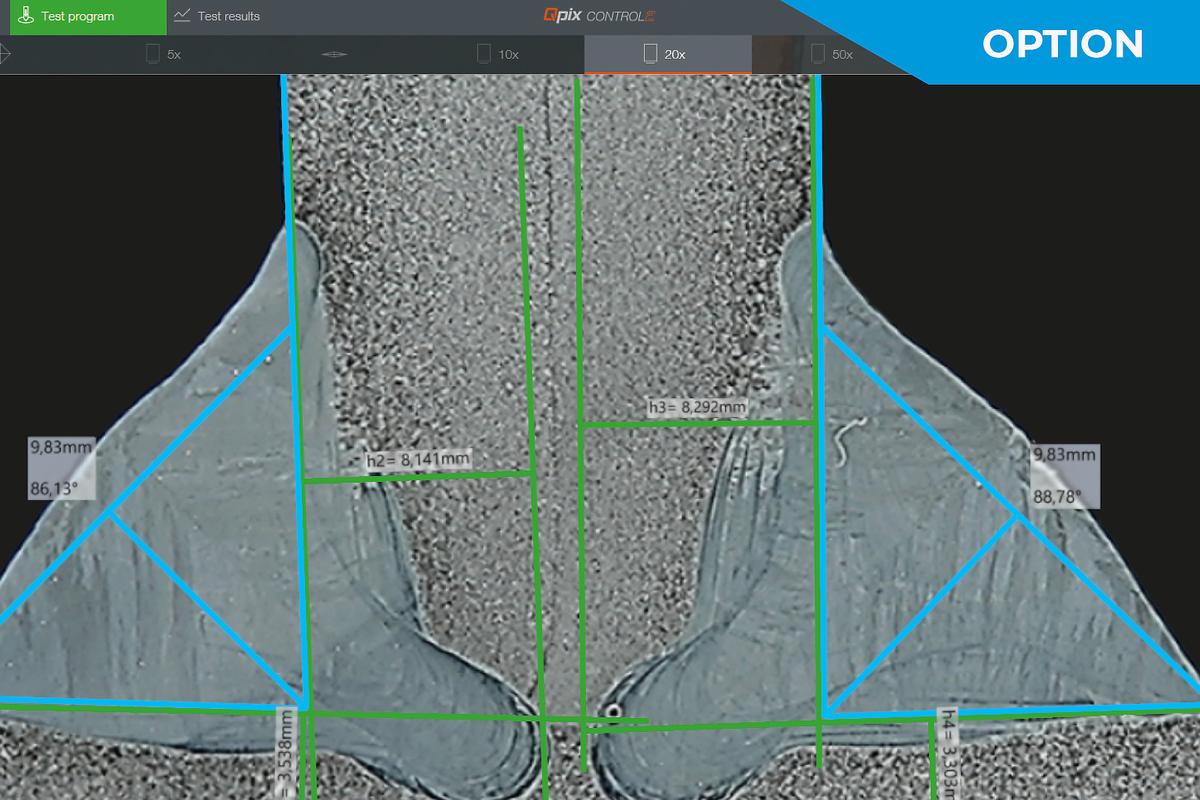

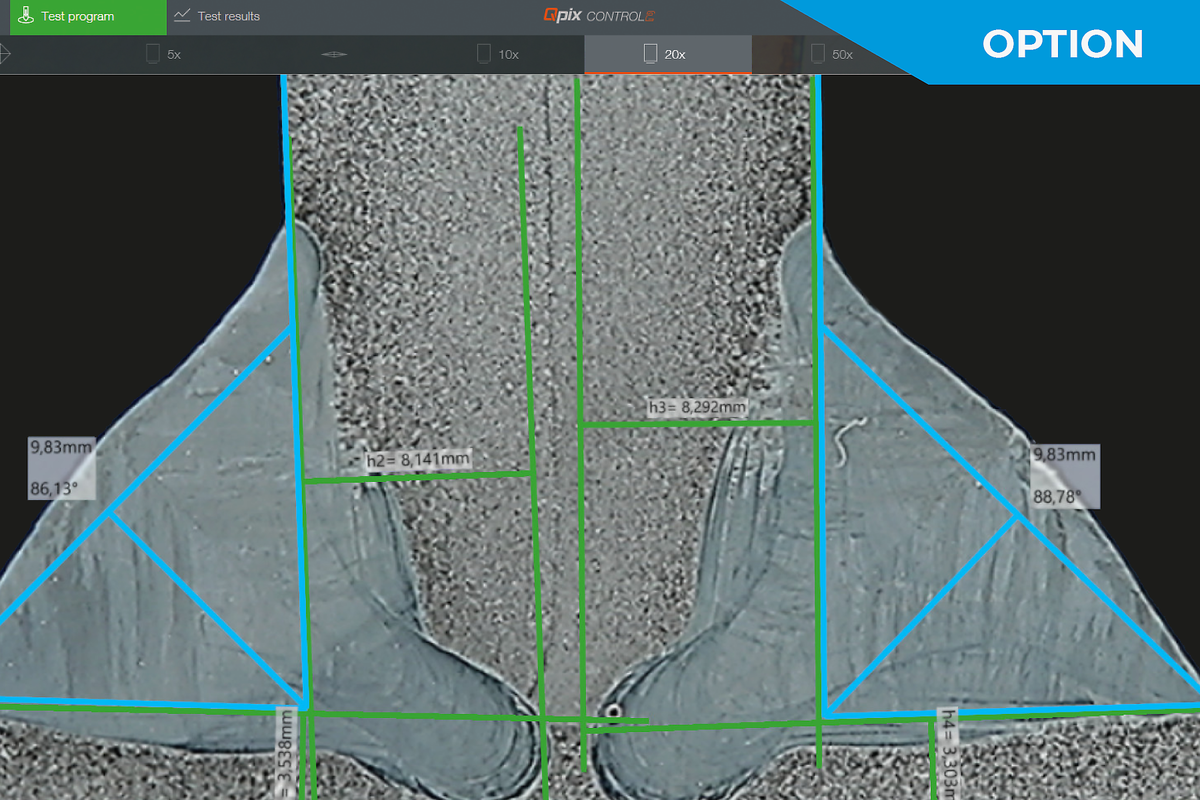

WELD SEAM MEASUREMENT

DIN EN ISO 5817

Standardised measurement and evaluation of weld seams Prefabricated templates with all relevant measuring tools such as throat thickness, weld reinforcement, penetration depth, etc. Automatic good/bad evaluation and report generation

IOT - INTERNET OF THINGS THE PLATFORM FOR REMOTE ACCESS TO YOUR DEVICES

All QATM hardness testers with QpixControl2 and QpixT2 software seamlessly integrate into the Verder Scientific IoT platform, providing enhanced functionality and seamless connectivity.

- Real-time Monitoring: Monitor your machinery in real time, from anywhere in the world. This data-driven approach empowers you to make informed decisions with ease.

- Live Notifications: Be ahead of the curve with immediate alerts and updates. Real-time notifications ensure you stay informed about your equipment's performance, leading to proactive maintenance.

- Effortless Backup: Simplify your data protection. Whether you need to back up a single device or an entire fleet, our platform streamlines the process, minimizing downtime and data loss.

- Automatic & Free Software Updates: Bid farewell to manual updates! Verder Scientific IoT ensures your customers' machines are consistently equipped with the latest software, optimizing performance and reliability.

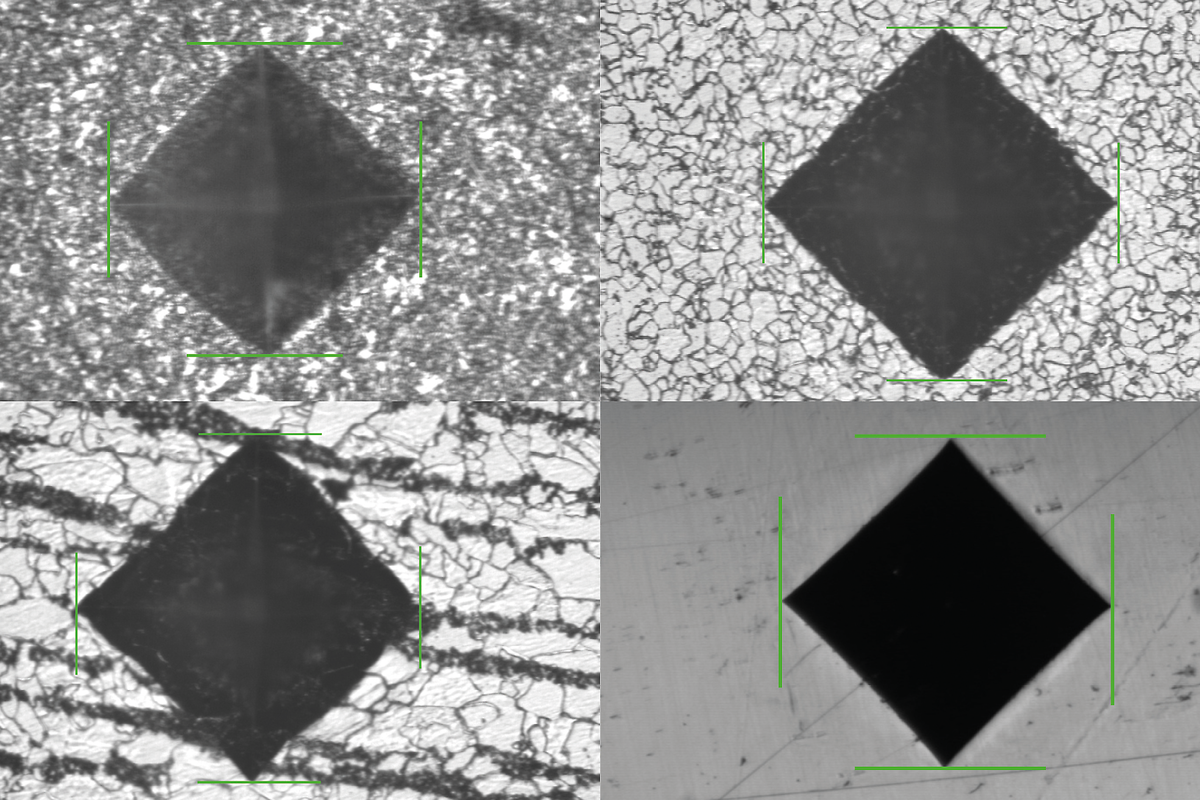

QNESS 10 / 60 A+ REVOLUČNÍ OPTICKÝ SYSTÉM

Tvrdoměry jsou osazeny objektivy, které si QATM vyrábí vlastní, a to přímo na míru, aby vyhověly i těm nejpřísnějším požadavkům. Vynikající objektivy dále doplňuje Koehlerovo osvětlení (bíle LED) s motorizovanou automatickou clonou pro vytvoření ideálního kontrastu i pro obrázky s velkým zvětšením. Pro strukturní analýzy se používá řada objektivů HQ s korekcí barev. K dispozici jsou i dva kamerové systémy 5MPx a 18MPx. Zkušení metalurgové mohou potvrdit, že kvalita obrazu poskytovaná Qness 10 / 60 A+ je ve všech aspektech srovnatelná s kvalitou zavedených sofistikovaných mikroskopů.

The up-to-date concept and new lenses in the optic system enable the device to completely meet even the strictest physical ‘test system definition’ requirements in compliance with DIN EN ISO6507-1/2:2018.

QNESS 10 / 60 A+ INNOVATIVE OPERATION

TEST SPACE LIGHTNING All devices are equipped with the new LED work space lighting: Simplified positioning of samples for single-piece tests.

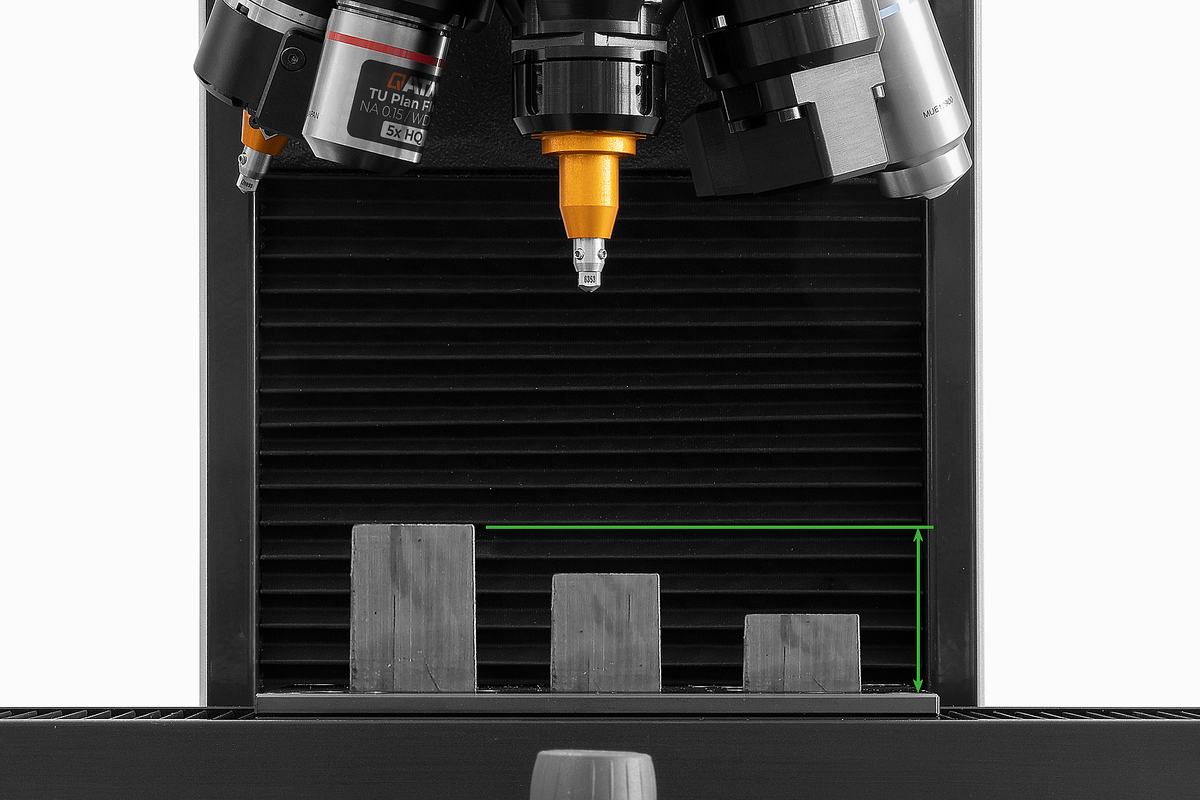

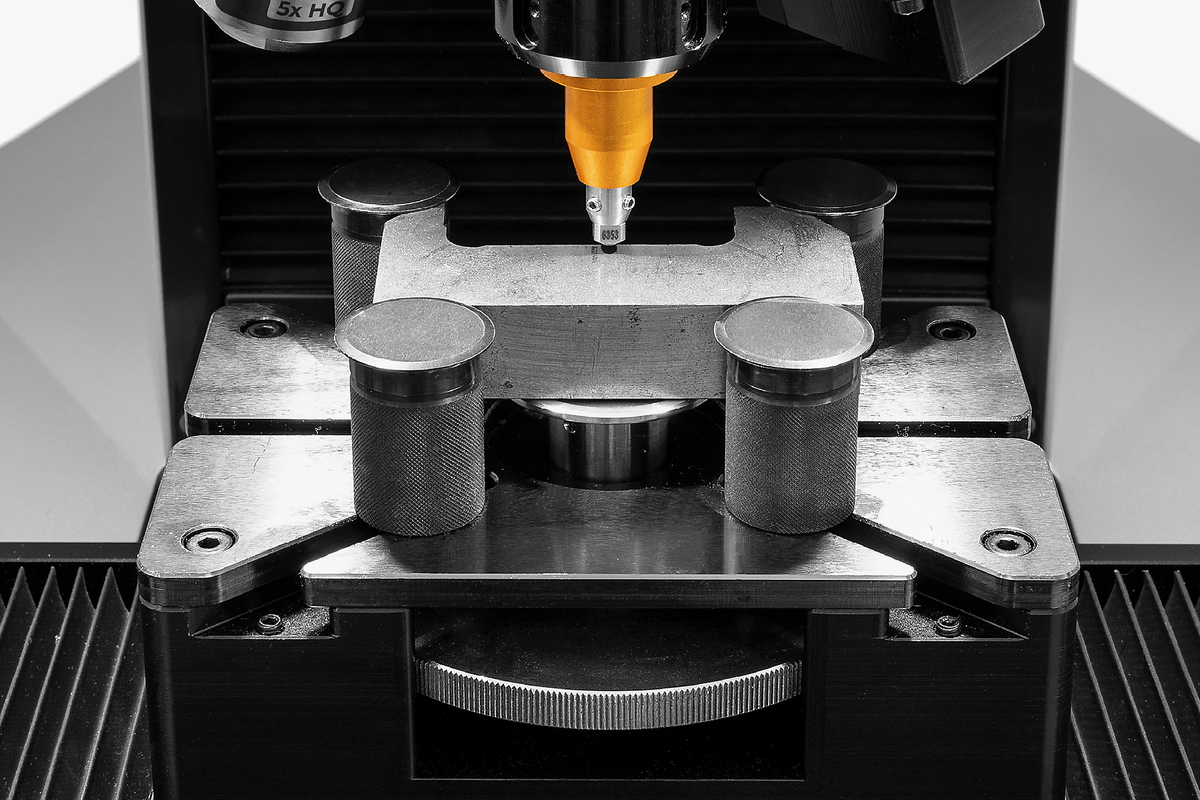

TEST SPACE LIGHTNING All devices are equipped with the new LED work space lighting: Simplified positioning of samples for single-piece tests.  VERTICAL CONCEPT WITH 2 Z-AXES There are decisive benefits in distributing vertical movement across 2 axes. Via the first Z-axis there is dynamic motion control, allowing the indenter to be positioned towards the test surface quickly and conveniently at up to 30mm§ss. The additional second Z-axis in the QATM system offers a high-resolution positioning system for greater precision in force application and focusing.

VERTICAL CONCEPT WITH 2 Z-AXES There are decisive benefits in distributing vertical movement across 2 axes. Via the first Z-axis there is dynamic motion control, allowing the indenter to be positioned towards the test surface quickly and conveniently at up to 30mm§ss. The additional second Z-axis in the QATM system offers a high-resolution positioning system for greater precision in force application and focusing.  8-POSITION TOOL CHANGER Up to 8 different test diamonds or lenses can be mounted to the ultra-modern turret of the Vickers / Knoop / Brinell hardness tester. The compact structure is angled at 20° to guarantee excellent test room visibility. Highlight: The newly developed hardness testing modules serve as modular indenter holders enabling plug-and-play retrofitting of Brinell and Knoop test equipment at any time after delivery.

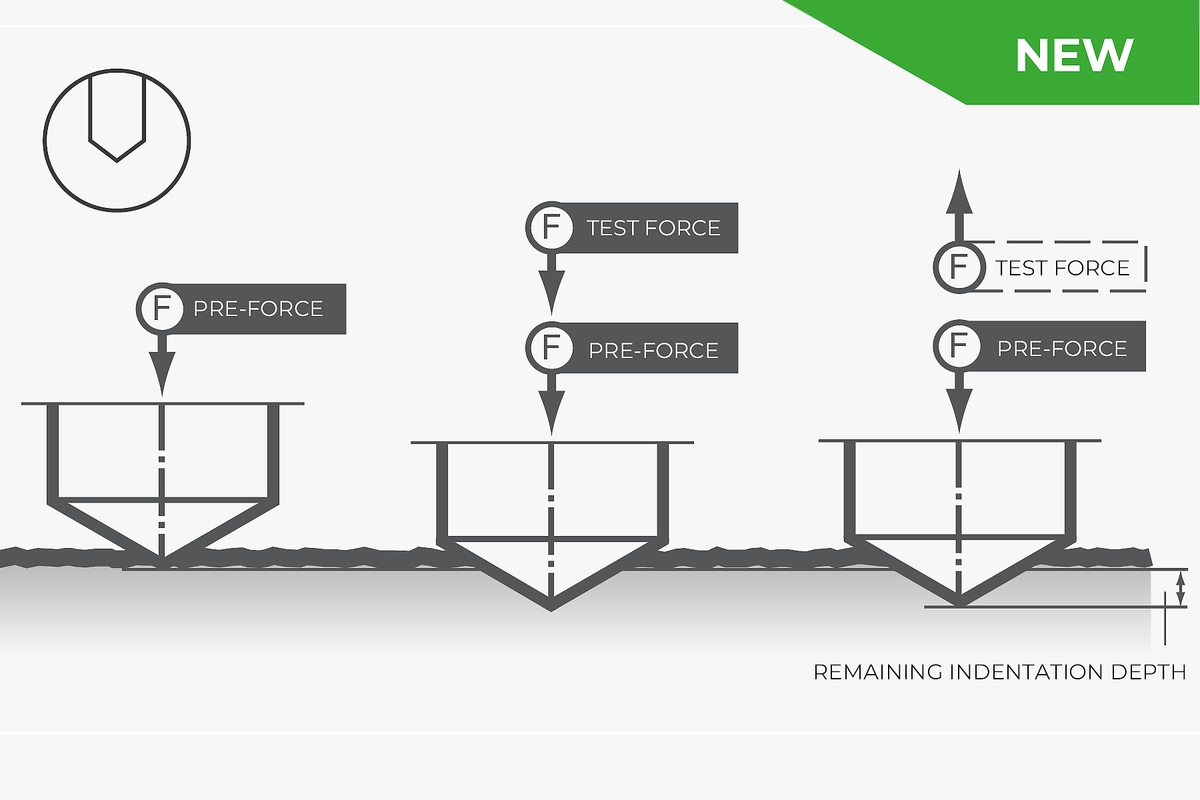

8-POSITION TOOL CHANGER Up to 8 different test diamonds or lenses can be mounted to the ultra-modern turret of the Vickers / Knoop / Brinell hardness tester. The compact structure is angled at 20° to guarantee excellent test room visibility. Highlight: The newly developed hardness testing modules serve as modular indenter holders enabling plug-and-play retrofitting of Brinell and Knoop test equipment at any time after delivery.  NEW ROCKWELL TEST METHOD In addition to the Vickers, Knoop and Brinell optical methods, Rockwell measurements can now also be carried out with the new micro hardness testers. A special Rockwell test module has been developed for this purpose.

NEW ROCKWELL TEST METHOD In addition to the Vickers, Knoop and Brinell optical methods, Rockwell measurements can now also be carried out with the new micro hardness testers. A special Rockwell test module has been developed for this purpose.  CAS TECHNOLOGY Innovative Collision Avoiding System (CAS) technology protects the mechanical parts in the device using predictive 3D motion calculations to visualize the effects of collisions and operation errors.

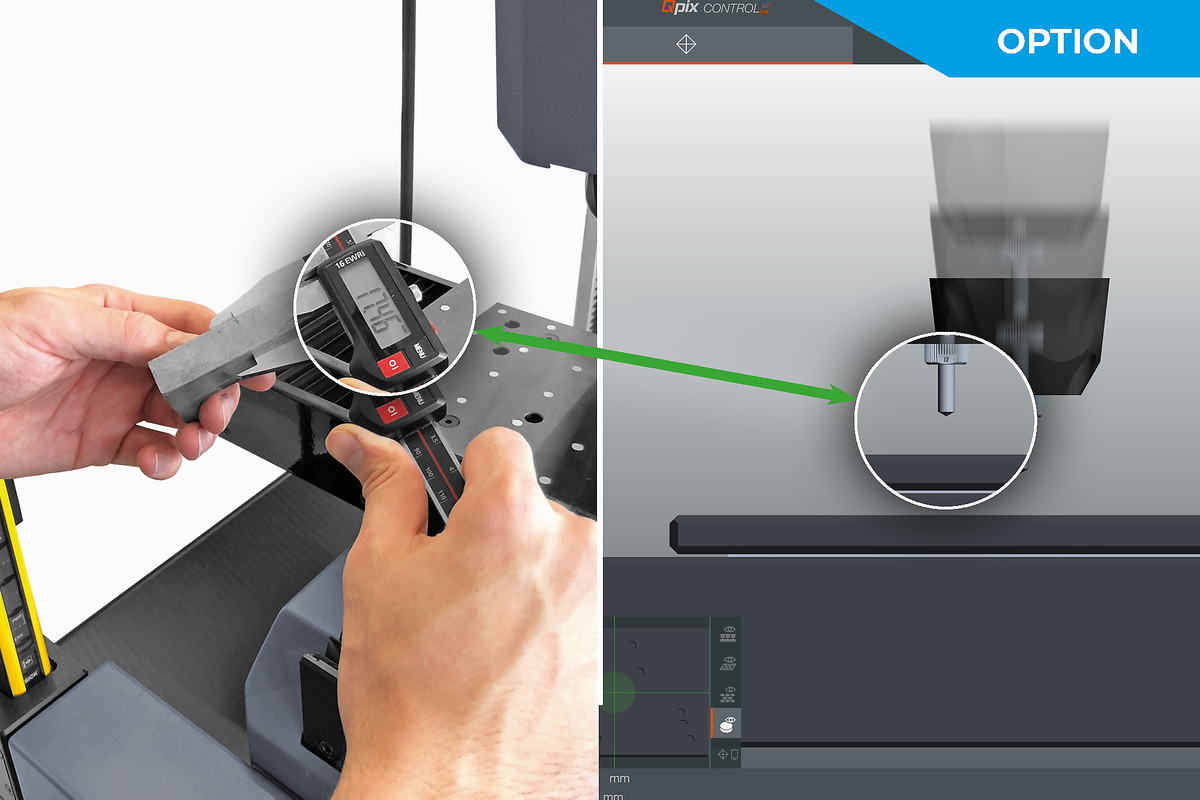

CAS TECHNOLOGY Innovative Collision Avoiding System (CAS) technology protects the mechanical parts in the device using predictive 3D motion calculations to visualize the effects of collisions and operation errors.  DIGITAL CALIPER The digital caliper is compatible with the Qpix Control2 system and reads the dimensions, height and diameter of components wirelessly and at the push of a button, entering them into the software. The test head height control in the A+ hardness tester enables the test height to be reached completely automatically with no need for manual input.

DIGITAL CALIPER The digital caliper is compatible with the Qpix Control2 system and reads the dimensions, height and diameter of components wirelessly and at the push of a button, entering them into the software. The test head height control in the A+ hardness tester enables the test height to be reached completely automatically with no need for manual input. ILLUMINATED STATUS DISPLAY BRINGS LIGHT INTO THE DARK

The illuminated QATM logo displays the current device status at a glance. The range of flash intervals indicates whether the device is operating automatically or is free to be used for new tasks for staff all around the lab. Furthermore, not only does the LED test space lighting, installed as standard, allow samples and sample holders to be set up correctly, in the A+ version it guarantees uniform light intensity for sample imaging.

QNESS 10 / 60 A+ PIONEERING TECHNOLOGY - UNIQUE IMPLEMENTATION

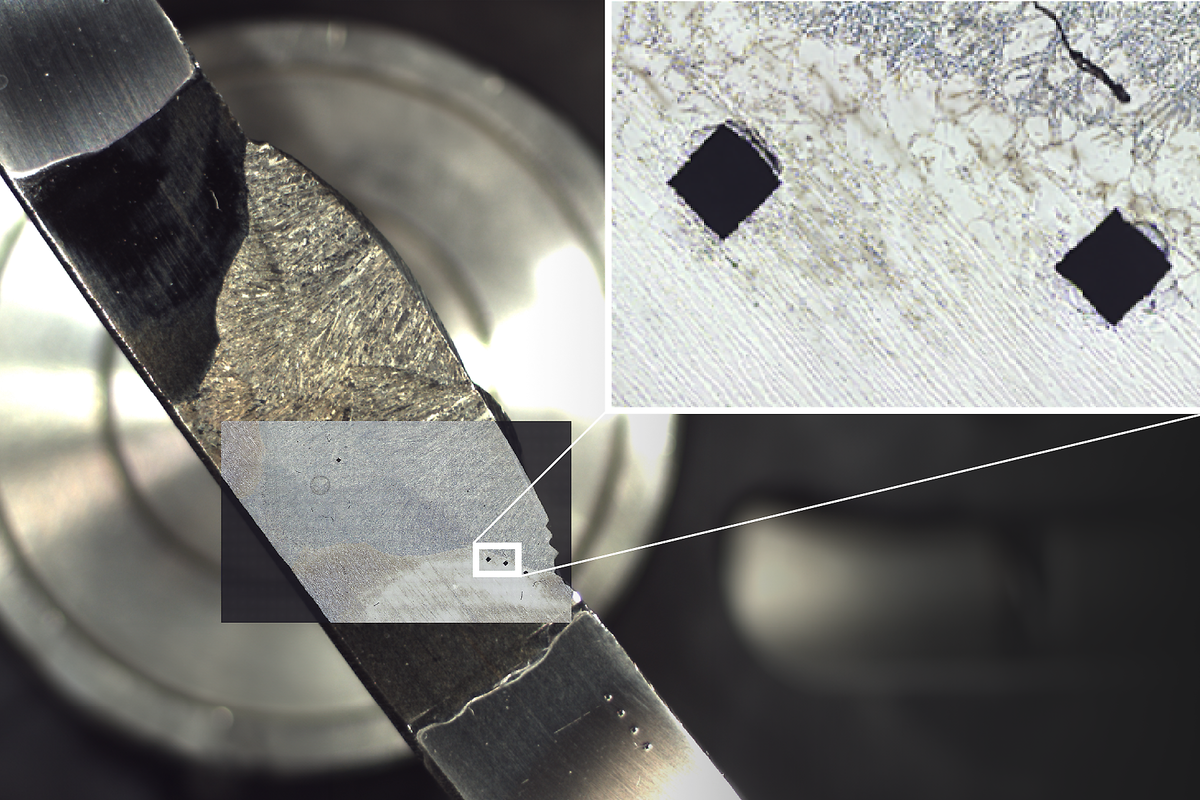

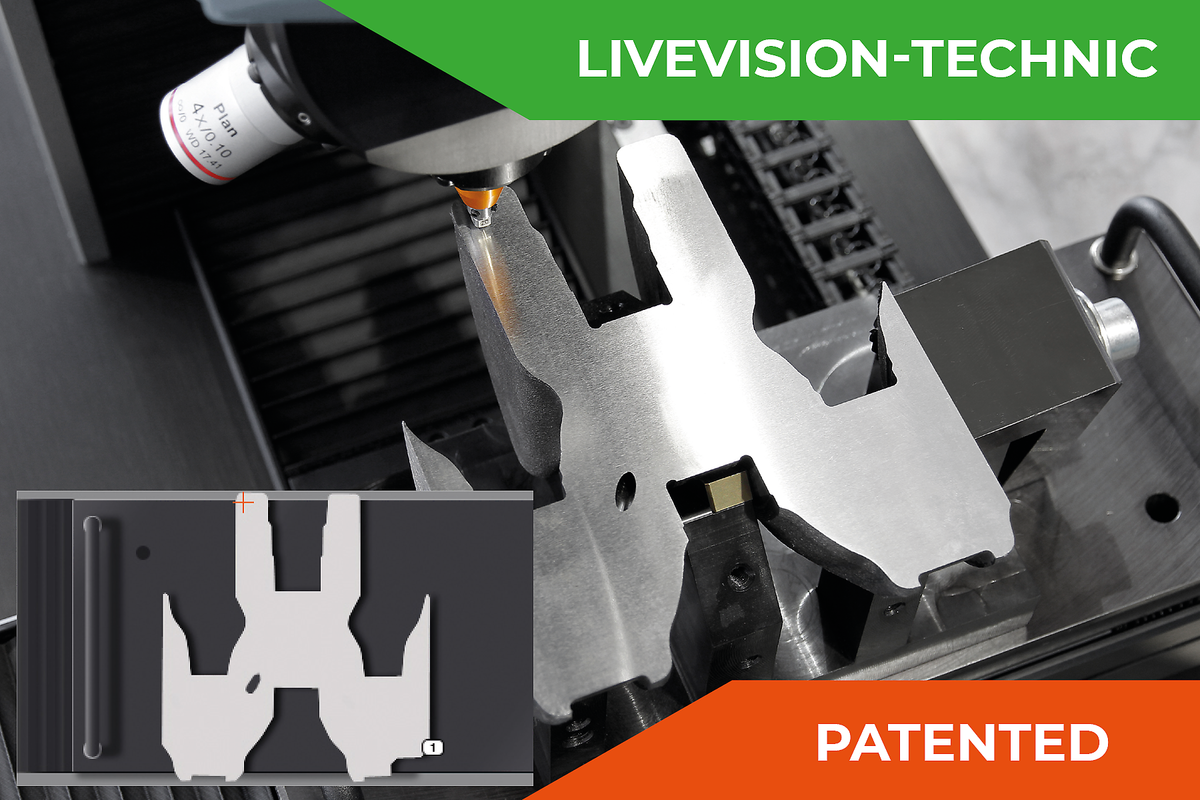

SAMPLE IMAGE CAMERA It's no coincidence that most QATM customers choose the ‘A+’ version with a built-in sample image camera. In a few seconds the image of the sample is shot with the additional camera (field of view 52 x 39 mm). The image provides excellent navigational support within the software, particularly in combination with DOUBLE- VIEW TECHNOLOGY, and aids enhanced documentation in the automatically compiled test report.

SAMPLE IMAGE CAMERA It's no coincidence that most QATM customers choose the ‘A+’ version with a built-in sample image camera. In a few seconds the image of the sample is shot with the additional camera (field of view 52 x 39 mm). The image provides excellent navigational support within the software, particularly in combination with DOUBLE- VIEW TECHNOLOGY, and aids enhanced documentation in the automatically compiled test report.  EXACT POSITIONING AND A LARGE TEST SPACE All 3 axes are equipped with incremental measuring system. The axes and turret can be positioned to an accuracy of 4 um, so the perfect solution for classic micro hardness testing. Series measurements can be repeatedly and accurately approached.

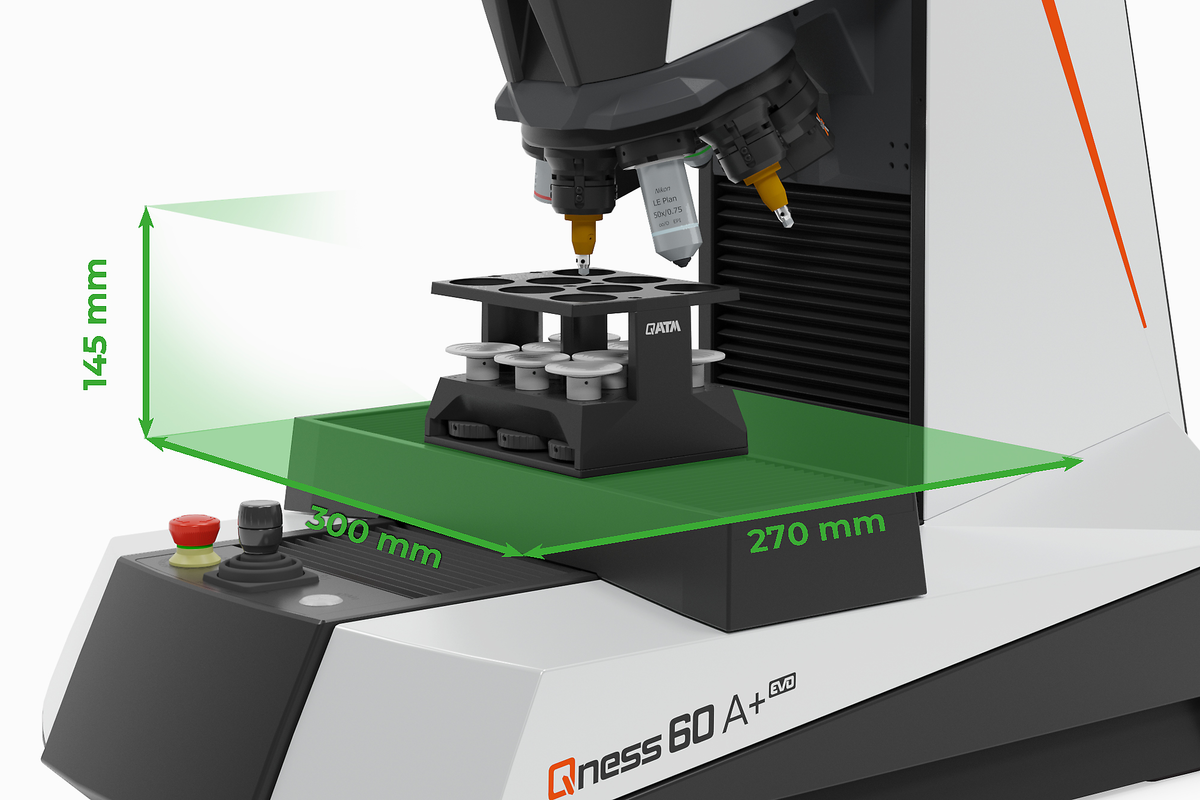

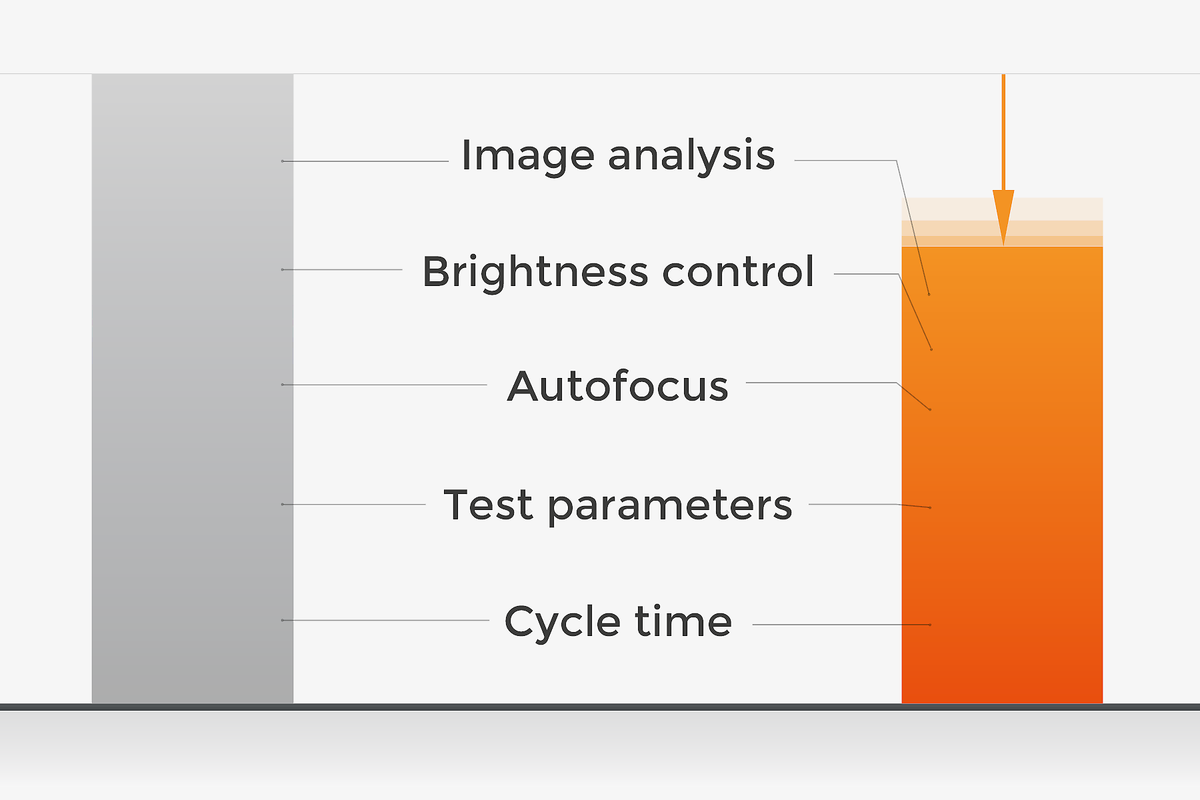

EXACT POSITIONING AND A LARGE TEST SPACE All 3 axes are equipped with incremental measuring system. The axes and turret can be positioned to an accuracy of 4 um, so the perfect solution for classic micro hardness testing. Series measurements can be repeatedly and accurately approached.  OPTIMIZED PERFORMANCE AND SILENCED DESIGN Optimized testing parameters and shorter intervals for serial autofocus, brightness regulation and image analysis, facilitate unbeatable cycle times during everyday operation involving hardness testing devices of the new micro hardness tester product line; and it’s even faster than the previous model. A further benefit of the new machine concept is the emphasis on reduced noise emissions in operation and motion, making it particularly suitable for laboratory work.

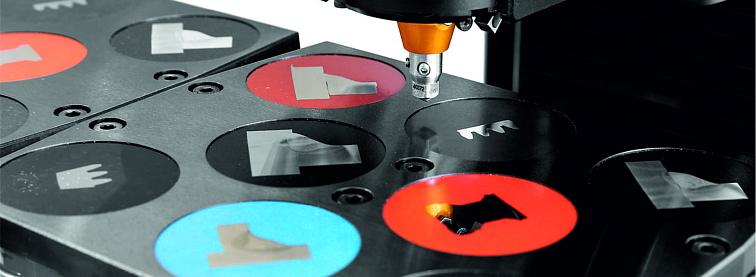

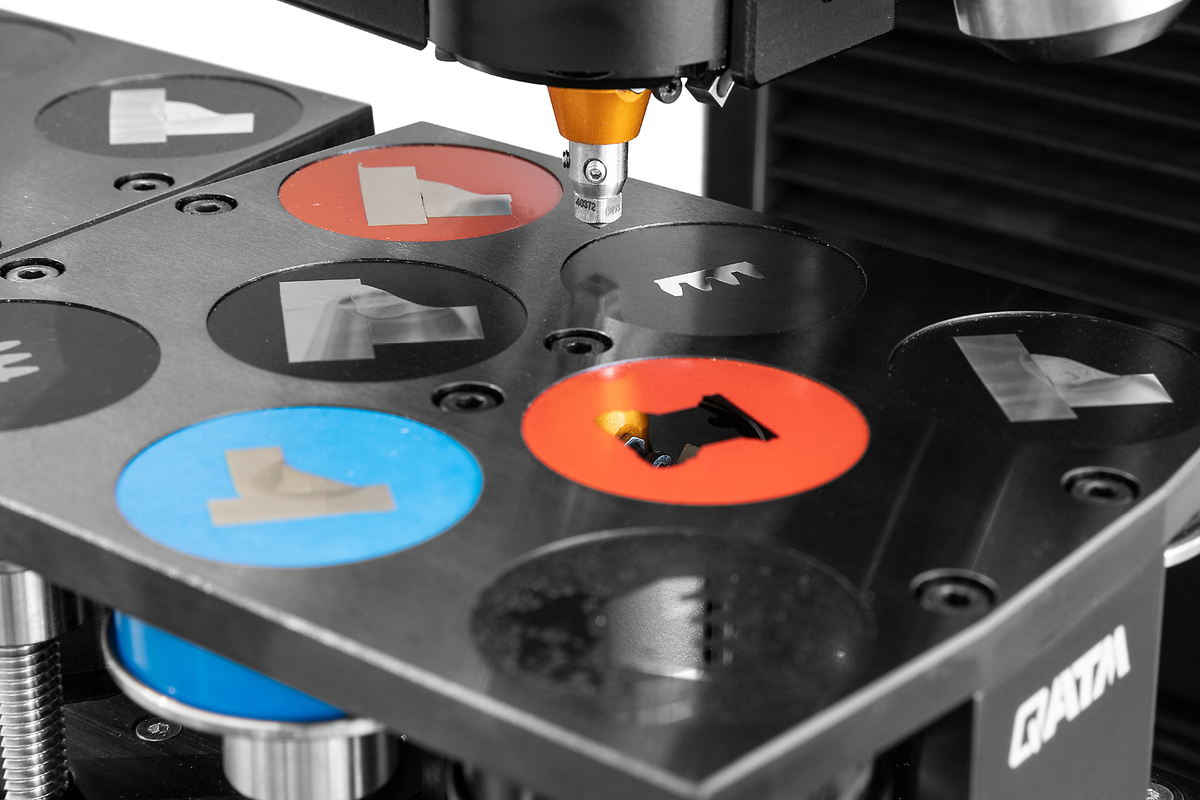

OPTIMIZED PERFORMANCE AND SILENCED DESIGN Optimized testing parameters and shorter intervals for serial autofocus, brightness regulation and image analysis, facilitate unbeatable cycle times during everyday operation involving hardness testing devices of the new micro hardness tester product line; and it’s even faster than the previous model. A further benefit of the new machine concept is the emphasis on reduced noise emissions in operation and motion, making it particularly suitable for laboratory work. 8-FOLD SAMPLE HOLDER PERFECTION IN FULL AUTOMATION

QATM sample holders are designed to ensure maximum throughput. ‘A+’ device test tables include enough space for an 8-fold sample holder as standard; up to two holders can be used in parallel with the optional 300 mm slide.

QNESS 10 / 60 A+ SAMPLE HANDLING FOR INDIVIDUAL & SERIES TESTING

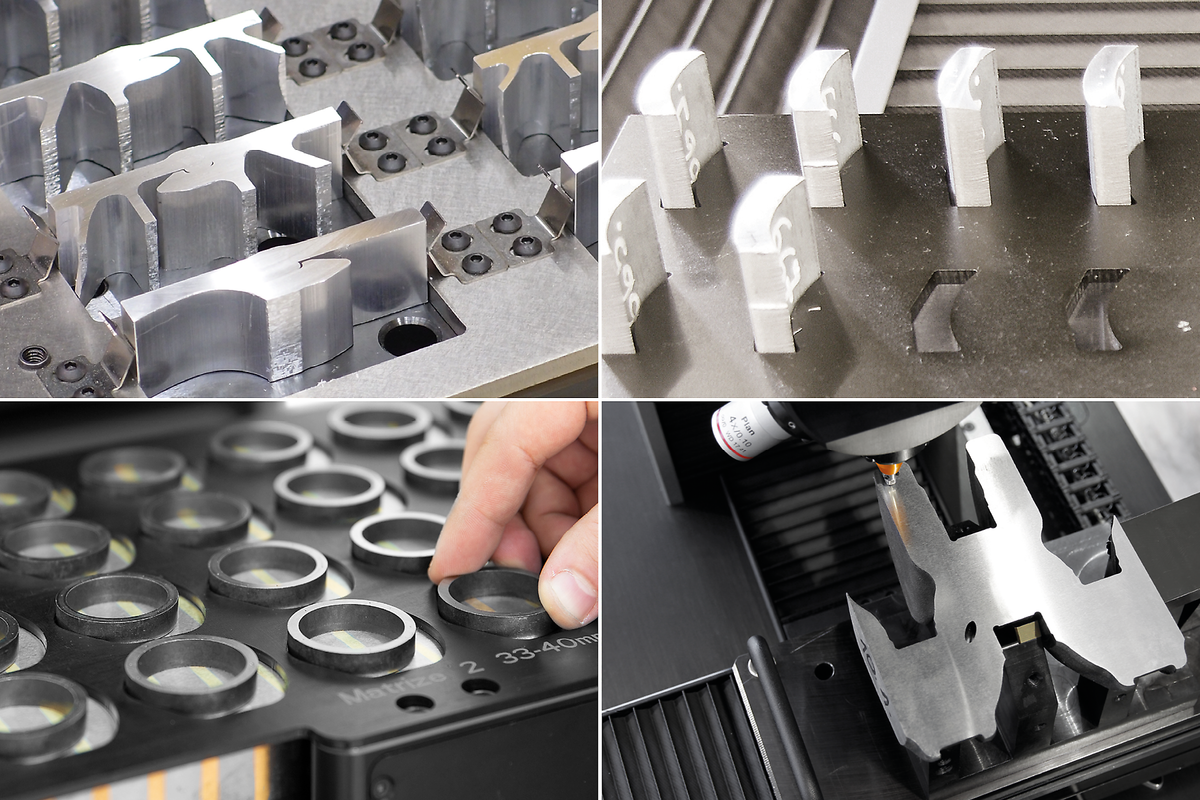

EMBEDDED SAMPLES The secure clamping of samples thanks to a redesigned holder with a built-in clamping force limiter, simplifies sample centering and positioning. A plate with a ball-joint even clamps specimen that cannot be held flat to prevent tilting or sliding during analysis. Available with 1, 4 or 8 holding positions and adapter rings for a large range of metric and imperial sample diameters.

EMBEDDED SAMPLES The secure clamping of samples thanks to a redesigned holder with a built-in clamping force limiter, simplifies sample centering and positioning. A plate with a ball-joint even clamps specimen that cannot be held flat to prevent tilting or sliding during analysis. Available with 1, 4 or 8 holding positions and adapter rings for a large range of metric and imperial sample diameters.  IDENTICAL SAMPLE TESTS An entire range of relevant data, such as test patterns, test methods and user fields can be activated via pre-defined sample magazines. QATM can provide the most suitable clamping setup, matrices and cassette systems for every requirement.

IDENTICAL SAMPLE TESTS An entire range of relevant data, such as test patterns, test methods and user fields can be activated via pre-defined sample magazines. QATM can provide the most suitable clamping setup, matrices and cassette systems for every requirement.  PRISMS QATM prisms also enable round components to be tested with our devices. Benefit: Integration of the 3D model in the software automatically determines the center of the component and the highest point of each piece.

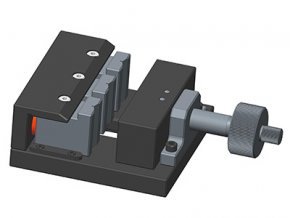

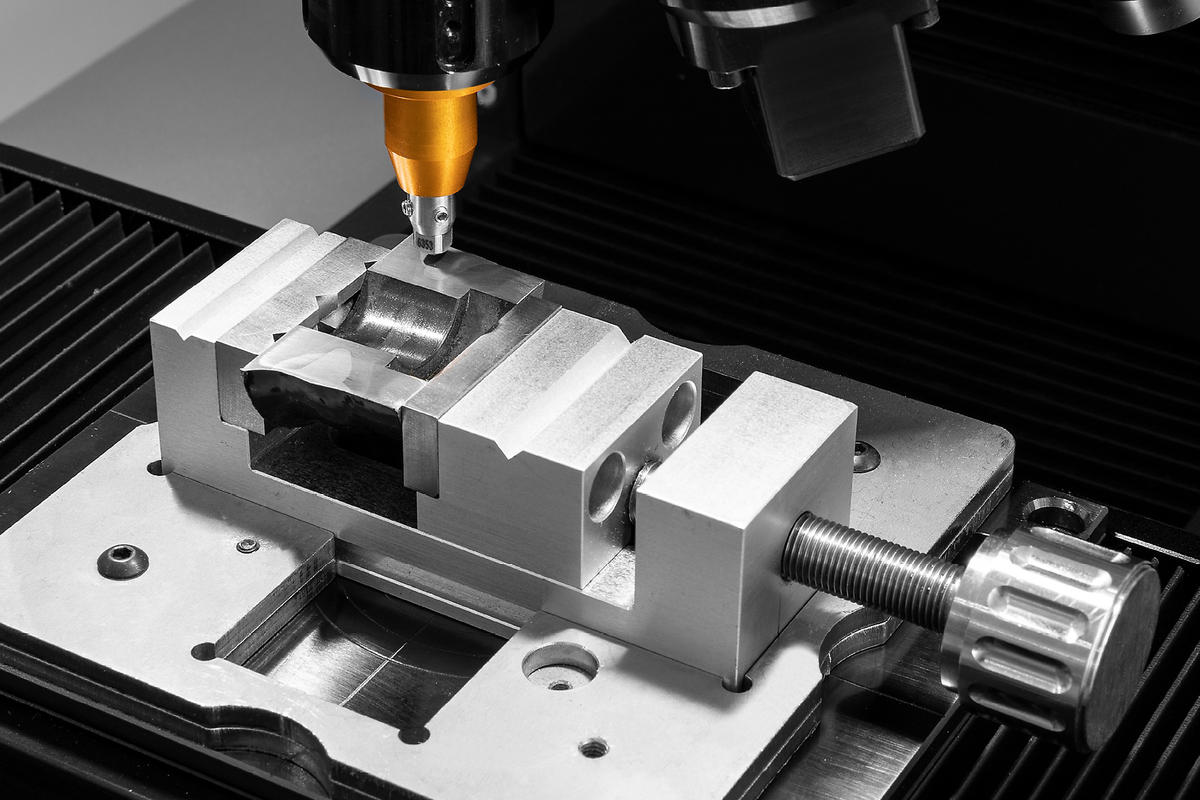

PRISMS QATM prisms also enable round components to be tested with our devices. Benefit: Integration of the 3D model in the software automatically determines the center of the component and the highest point of each piece.  VICES The clearly-organized, large and robust test room facilitates universality. Additionally, clamping samples straight into conventional vices reduces the effort required to prepare the sample, and expands the range of possible future test applications. QATM vices are also available with extra templates, enabling samples to be repeatedly clamped in precisely the same position.

VICES The clearly-organized, large and robust test room facilitates universality. Additionally, clamping samples straight into conventional vices reduces the effort required to prepare the sample, and expands the range of possible future test applications. QATM vices are also available with extra templates, enabling samples to be repeatedly clamped in precisely the same position. REVOLUTIONARY 3D OPERATING CONCEPT

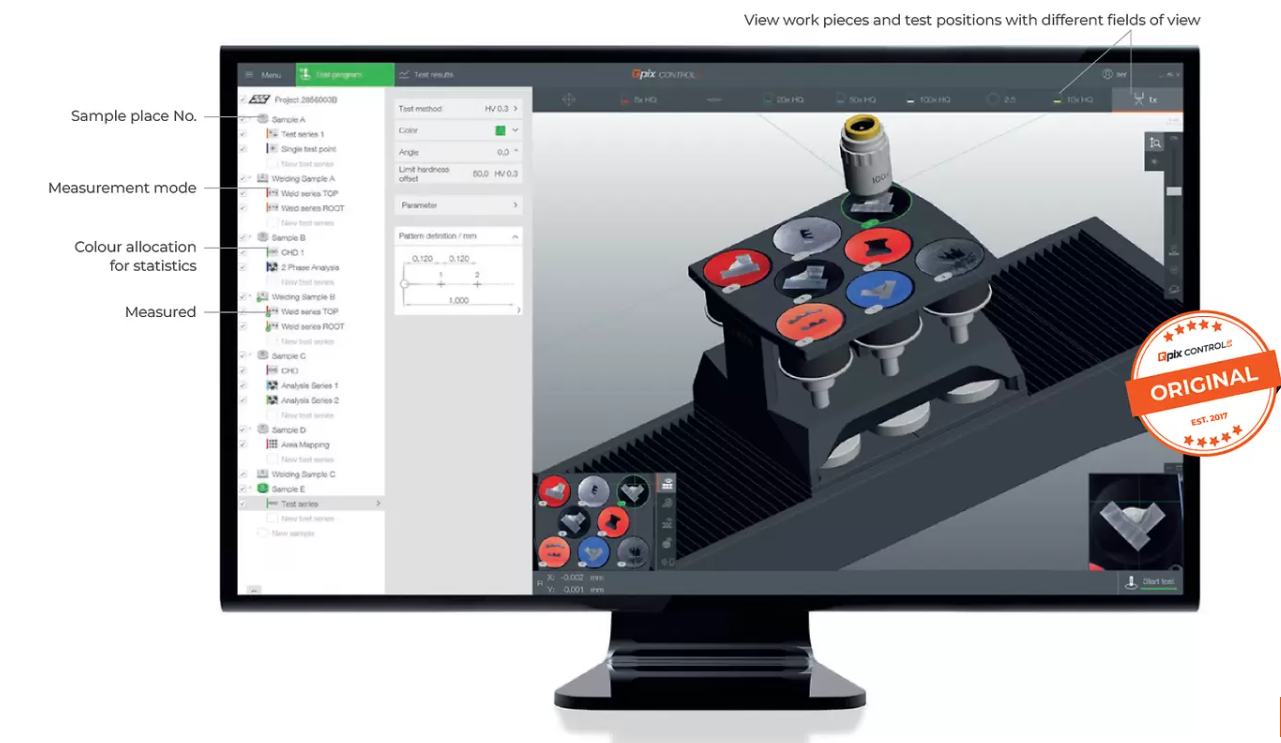

NEXT-GENERATION SOFTWARE FOR YOUR HARDNESS TESTER

Intuitive, clearly organized and professional: Qpix Control2 is a pc-operated, next-generation software for Brinell / Knoop / Vickers / Rockwell hardness testers, developed based on customer feedback and input for maximum user-friendliness. The controlled test head benefits from automatic height adjustment and contactless exploration, complete integration of the sample holder, CAD compatibility with 3D imaging and a whole range of easily understood 3D control elements and views included in the software. It sets new standards in hardness testing.LOAD SAMPLES, LOAD ROW, START 3 STEPS TO THE RESULT

QPIX CONTROL2 INNOVATIVE SOFTWARE FUNCTIONS

FULLY AUTOMATIC HARDNESS TESTING Several progessions and samples are created and completed "unmanned" (i.e. 60 progressions on 8 different samples in one test run)

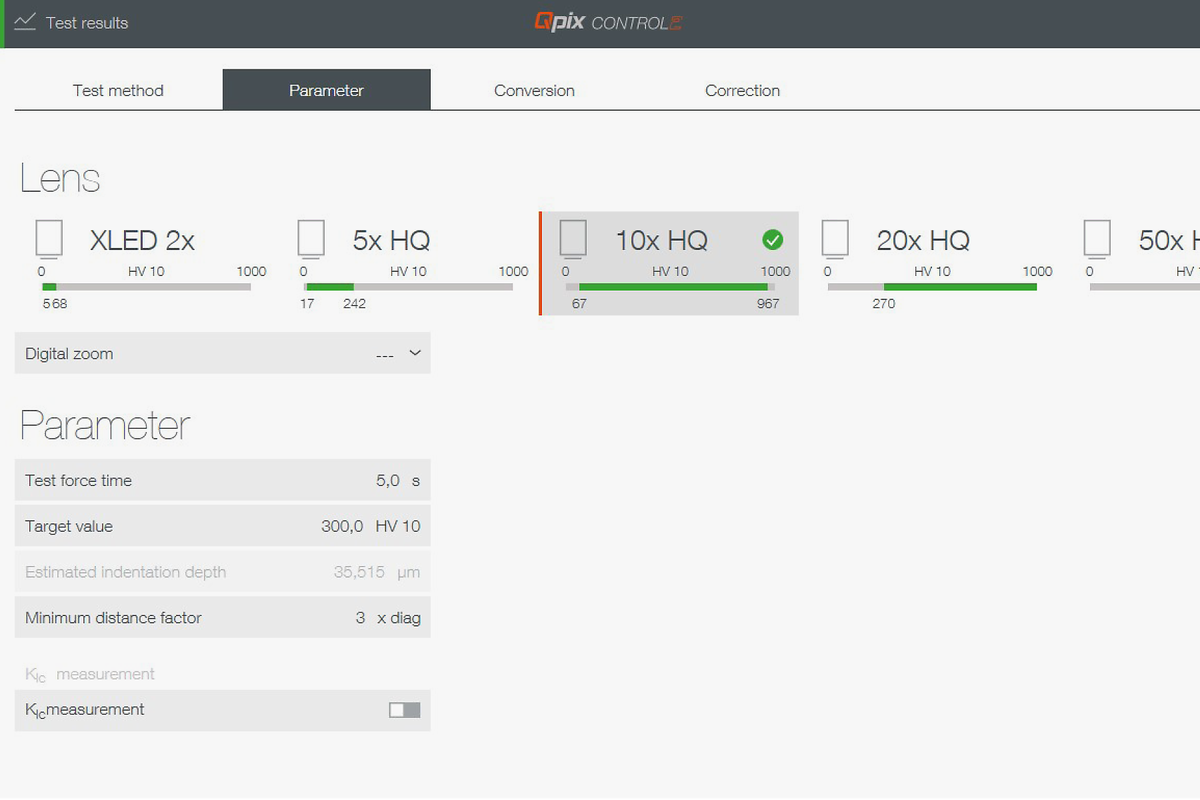

FULLY AUTOMATIC HARDNESS TESTING Several progessions and samples are created and completed "unmanned" (i.e. 60 progressions on 8 different samples in one test run)  SIMPLIFIED LENS SELECTION Based on the selected method (e.g. HV10), the suitable hardness range is displayed for each lens, which can be measured. The most suitable lens is also highlighted.

SIMPLIFIED LENS SELECTION Based on the selected method (e.g. HV10), the suitable hardness range is displayed for each lens, which can be measured. The most suitable lens is also highlighted.  DUAL SYSTEM With the Qpix Control 2 software, several QATM devices (for example a Qeye 800 and a Qness 60 A+ EVO) can be operated with the same PC system. It is easy to switch back and forth between the two devices in the software.

DUAL SYSTEM With the Qpix Control 2 software, several QATM devices (for example a Qeye 800 and a Qness 60 A+ EVO) can be operated with the same PC system. It is easy to switch back and forth between the two devices in the software.  TEMPLATE FUNCTION | Ideal for repeated tests / components | Alignment of ‘test point mappings’ directly on the work piece with reference lines and bench marks | Test point and analysis patterns without ‘fixed stop’ or sample holder | The sample image can be used in a clearly- structured test report

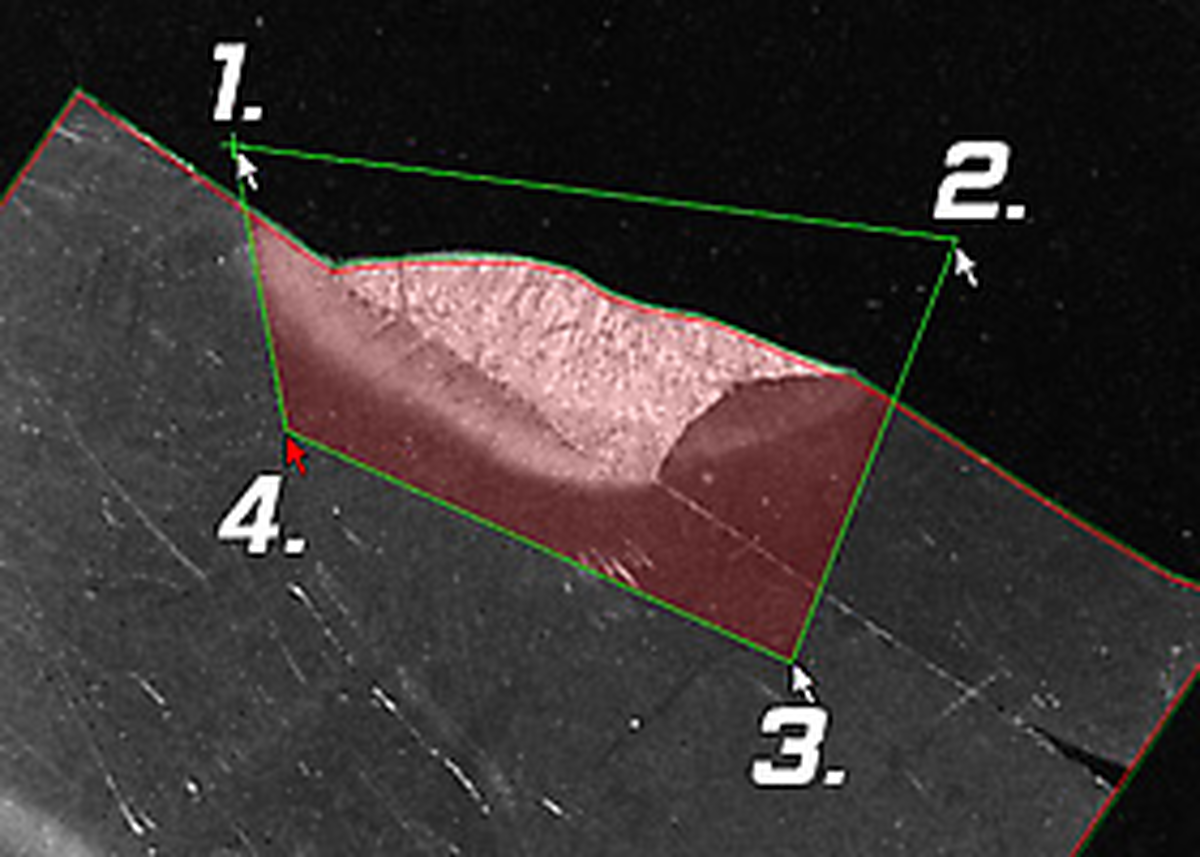

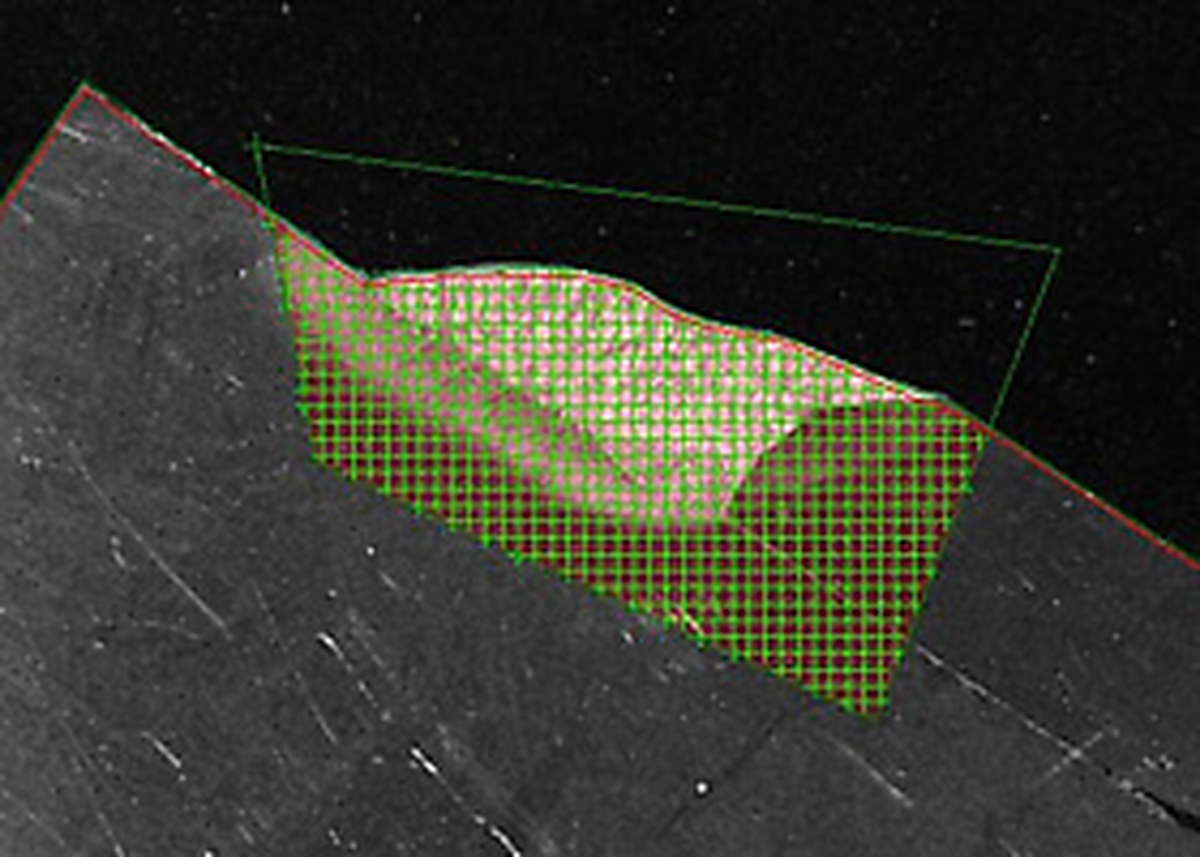

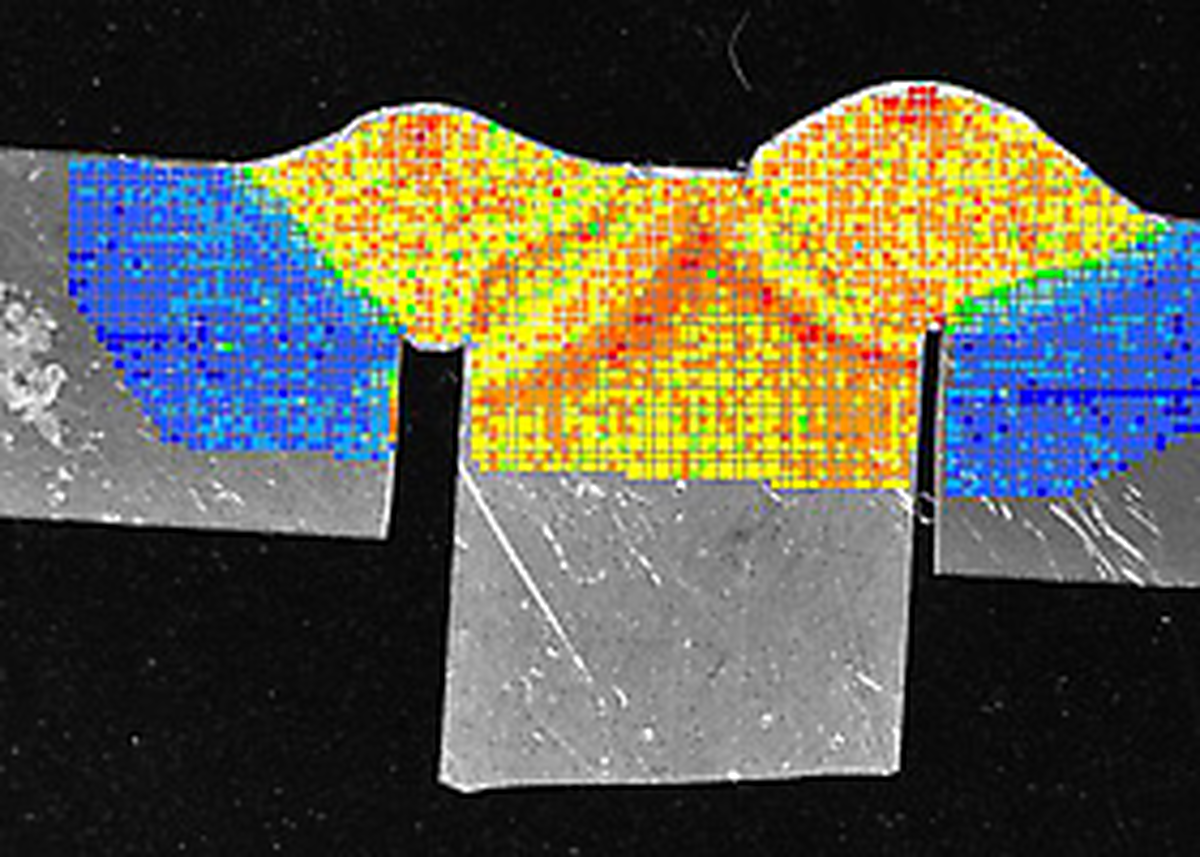

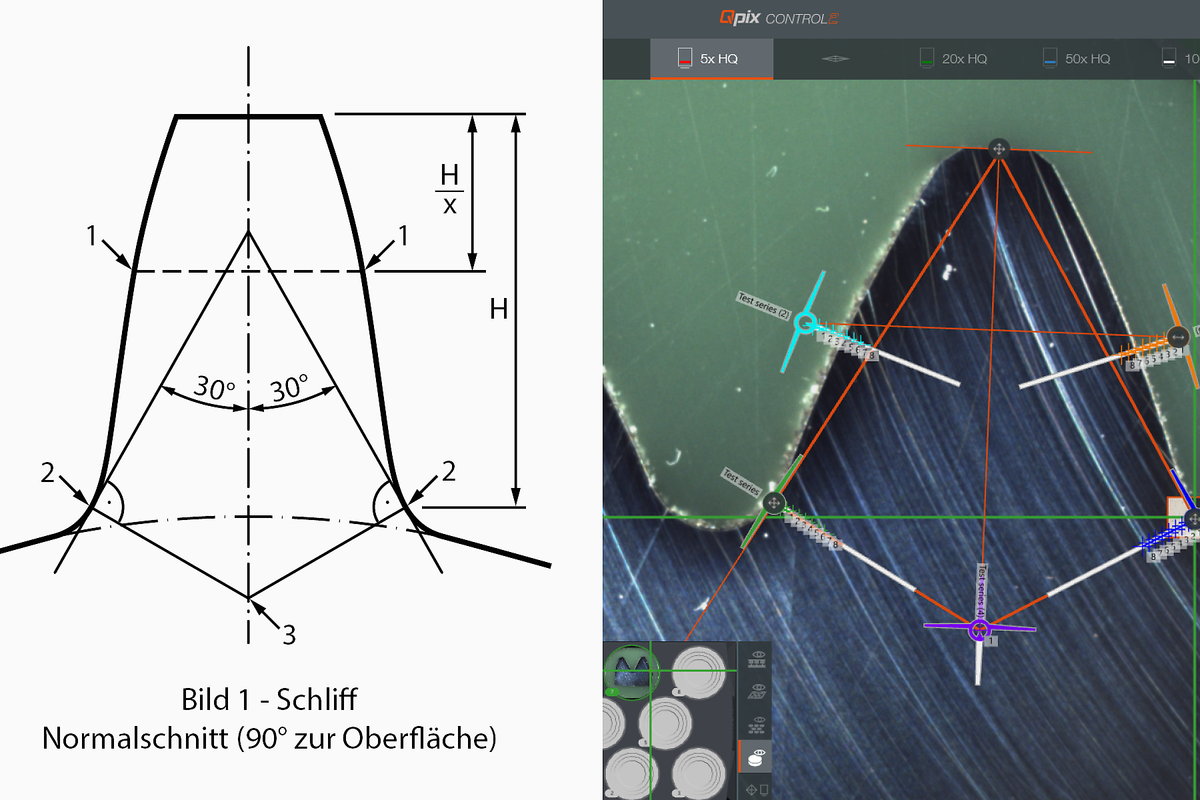

TEMPLATE FUNCTION | Ideal for repeated tests / components | Alignment of ‘test point mappings’ directly on the work piece with reference lines and bench marks | Test point and analysis patterns without ‘fixed stop’ or sample holder | The sample image can be used in a clearly- structured test report  WELD SAMPLE TESTING AND ANALYSIS Serial provision of ‘Advanced Welding’ functions facilitates the simple, norm- compliant (e.g. EN ISO 9015 & EN ISO 22826) integration of test mapping for Brinell / Knoop / Vickers hardness testing. Pre-defined patterns can be simply adapted to each respective test piece via interactive functions. If required, Qpix INSPECT modules can also provide a simultaneous material-graphics analysis of the weld seam.

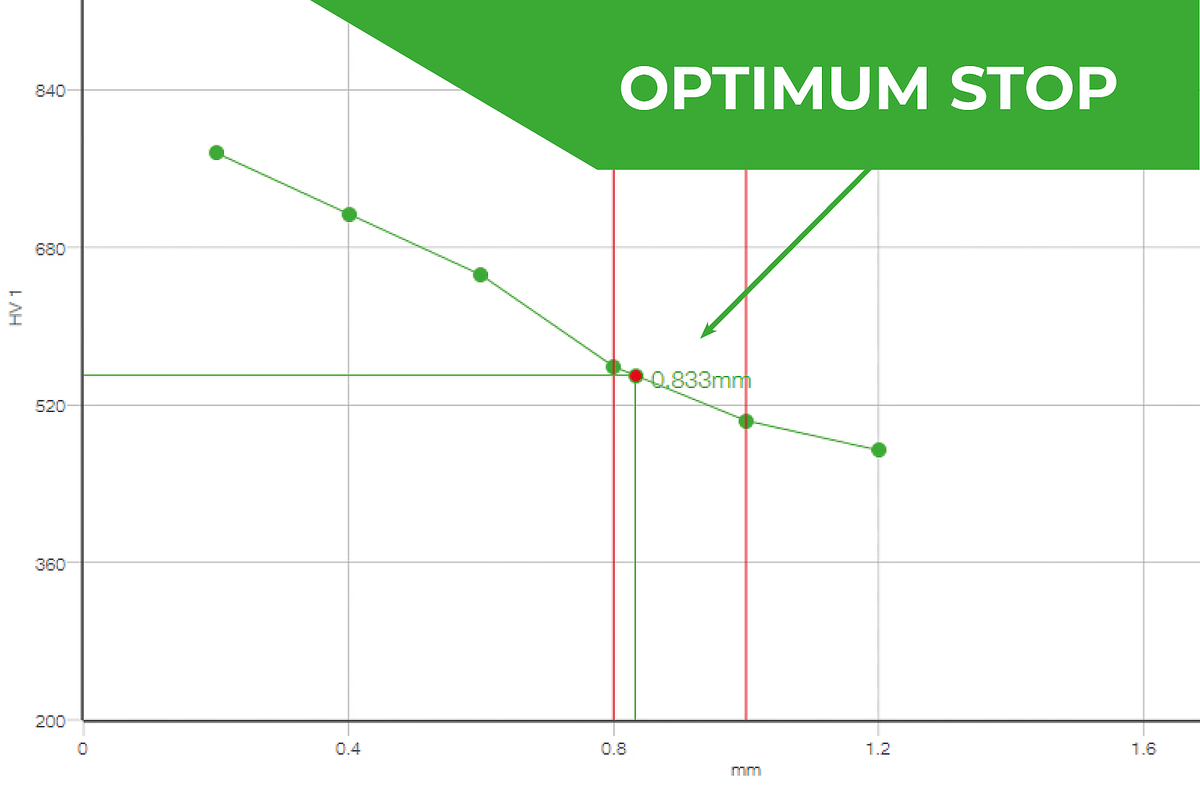

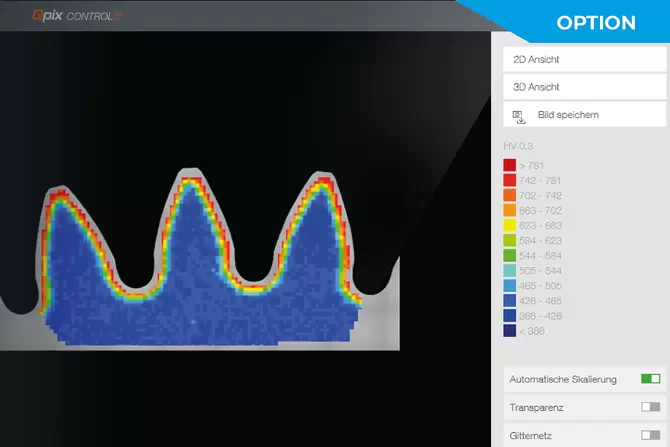

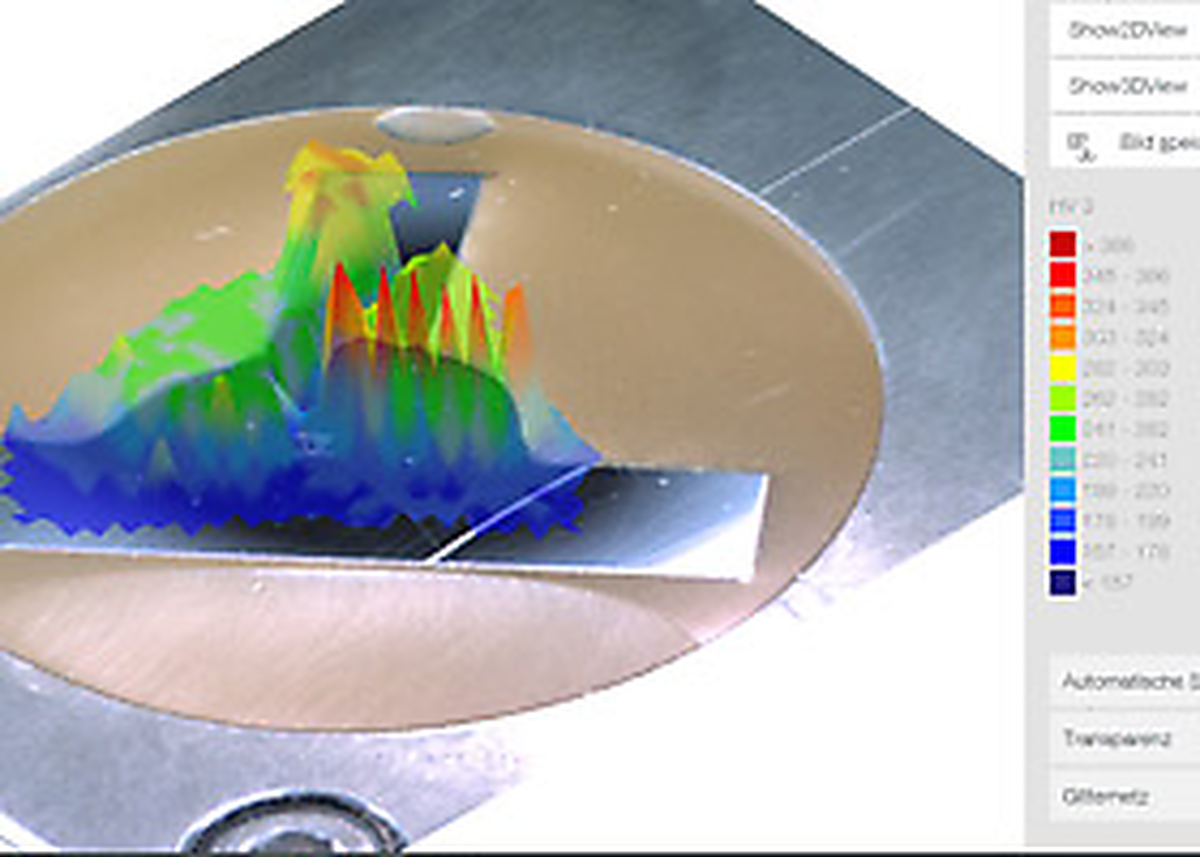

WELD SAMPLE TESTING AND ANALYSIS Serial provision of ‘Advanced Welding’ functions facilitates the simple, norm- compliant (e.g. EN ISO 9015 & EN ISO 22826) integration of test mapping for Brinell / Knoop / Vickers hardness testing. Pre-defined patterns can be simply adapted to each respective test piece via interactive functions. If required, Qpix INSPECT modules can also provide a simultaneous material-graphics analysis of the weld seam. OPTIONAL SOFTWARE MODULE 2D/3D HARDNESS CHART

The optional software module ‘2D/3D hardness chart’ is the perfect aid for the detailed determination of hardness distribution over the total cross section, especially for heat-treated materials. This is extremely important in material exploration, and also for weld testing or in damage analysis.

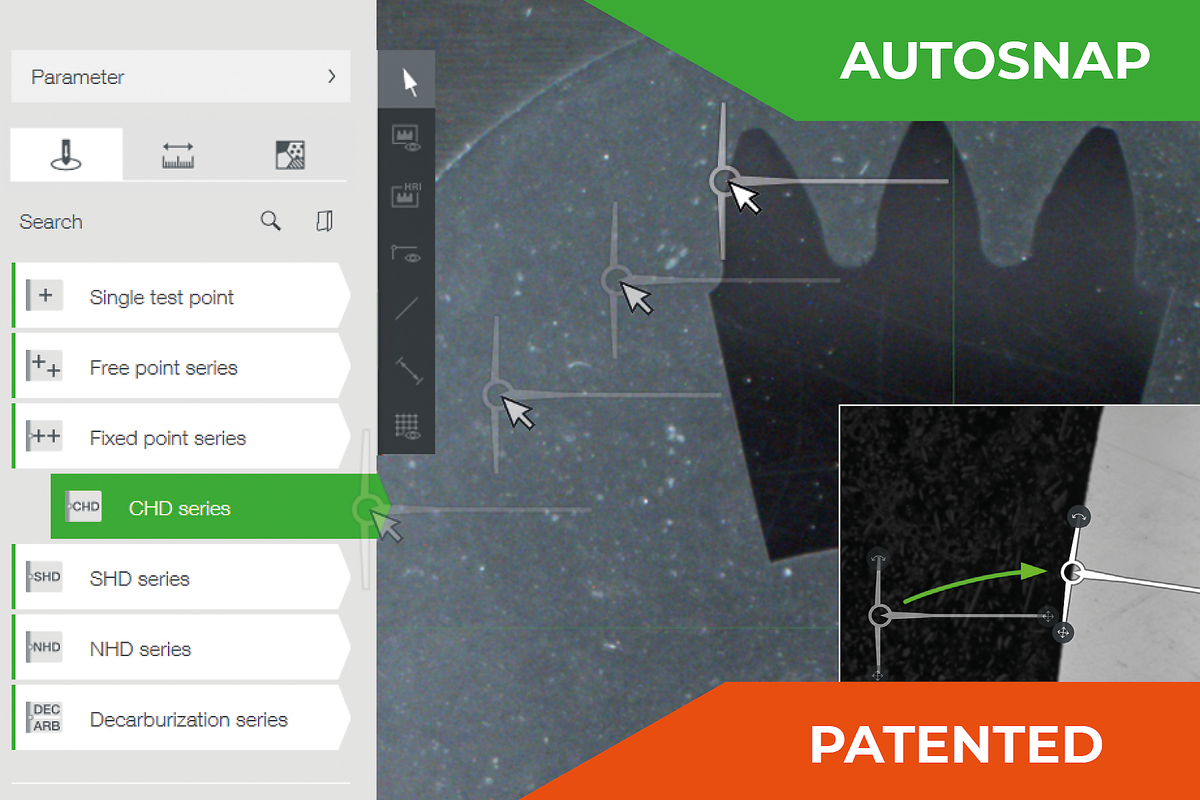

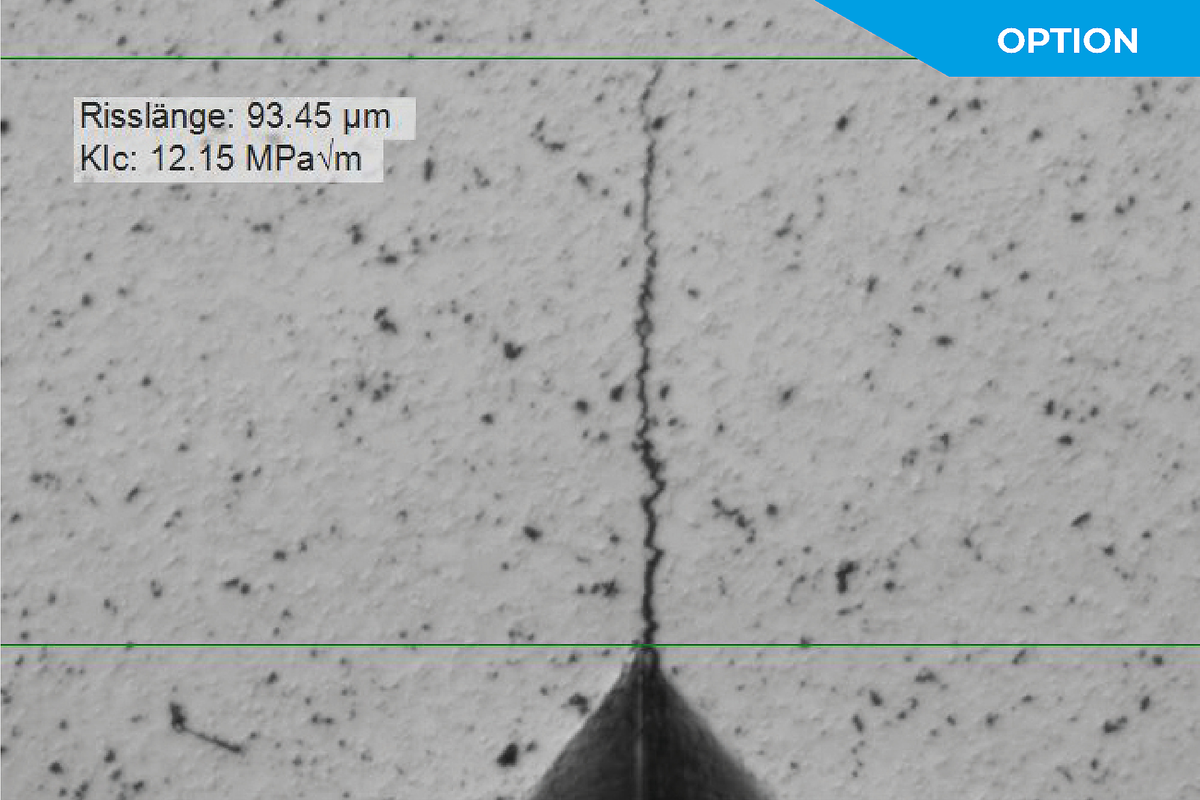

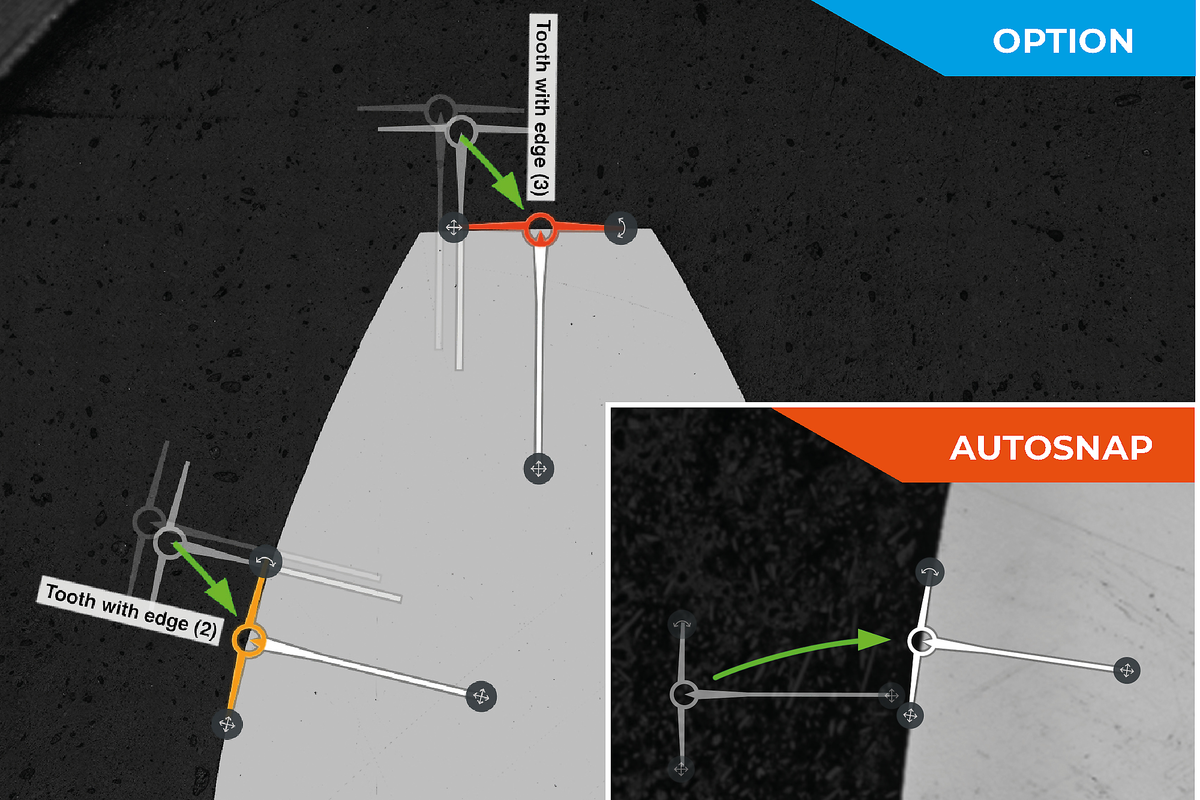

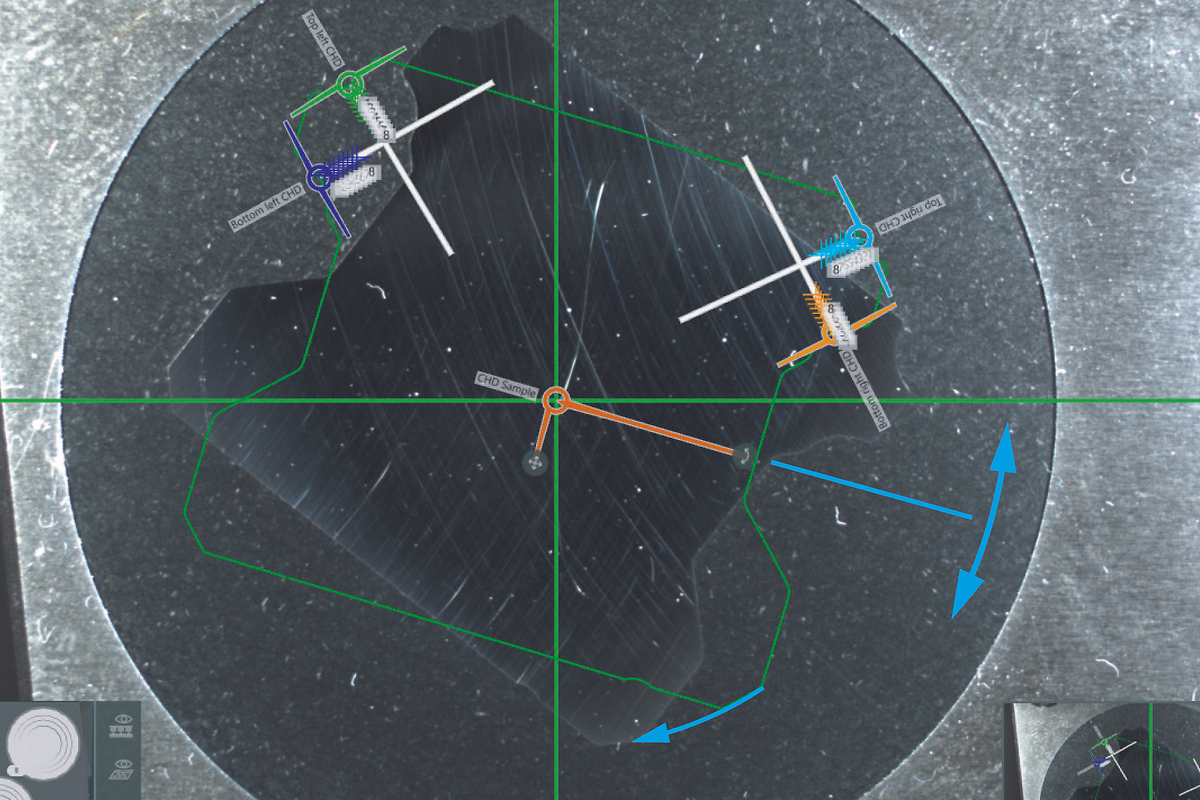

TOOTH FLANK TESTING The time-consuming creation of test points, especially with tooth flank testing, is minimized by means of pre-defined templates. The A+ version enables the entire normed procedure between HV30 and HV1 to be done by one single device.

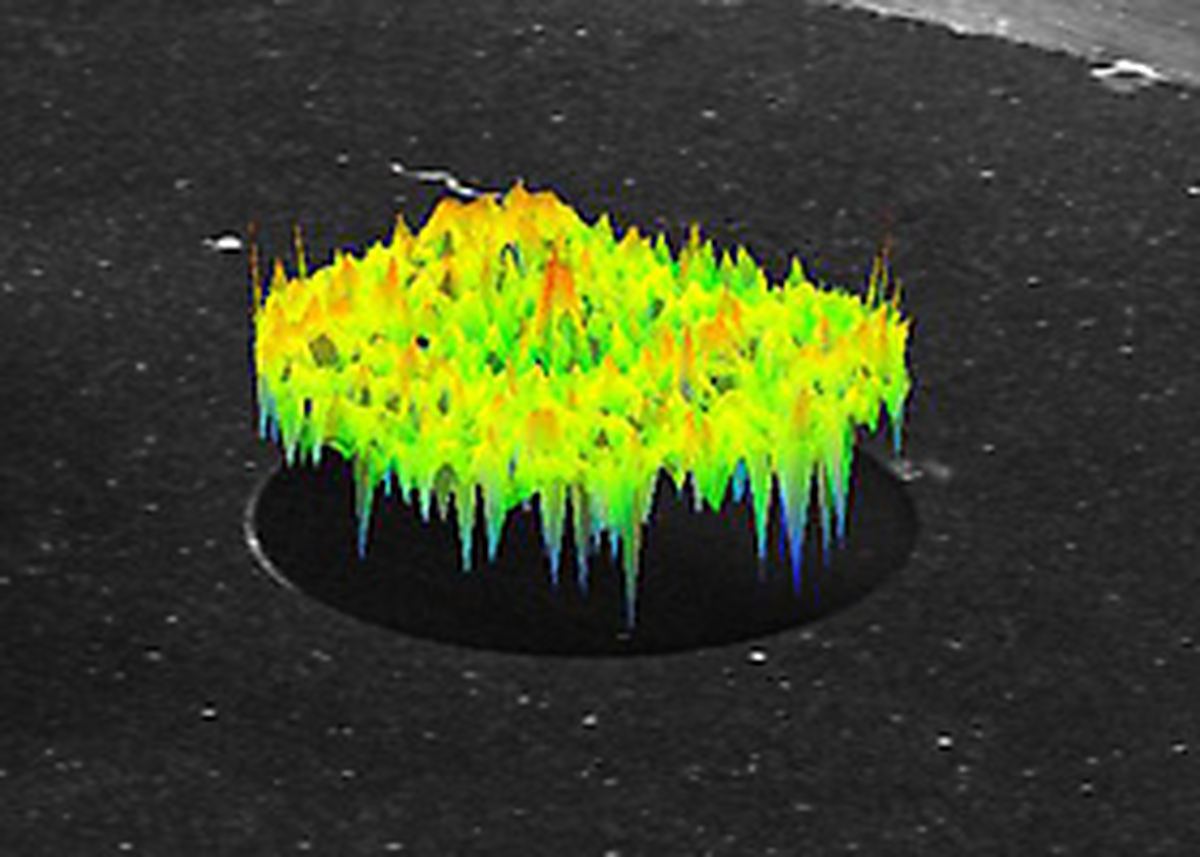

TOOTH FLANK TESTING The time-consuming creation of test points, especially with tooth flank testing, is minimized by means of pre-defined templates. The A+ version enables the entire normed procedure between HV30 and HV1 to be done by one single device.  MODULE FOR SINTERED COMPONENTS With this module, an area on the component can be easily defined and the number of hardness test points defined, especially for sintered samples. The software automatically searches for a position in the selected area where a hardness test indentation can be placed so that it is placed at a suitable location.

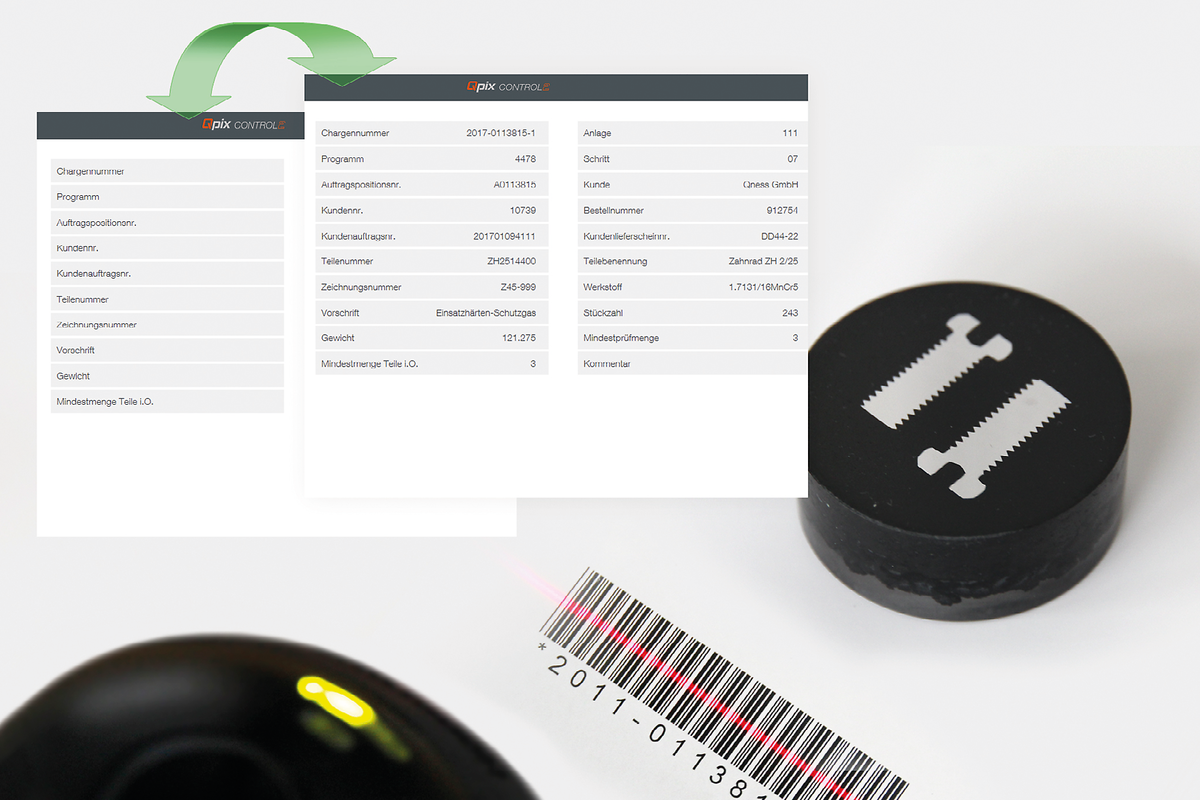

MODULE FOR SINTERED COMPONENTS With this module, an area on the component can be easily defined and the number of hardness test points defined, especially for sintered samples. The software automatically searches for a position in the selected area where a hardness test indentation can be placed so that it is placed at a suitable location.  BARCODE/QR CODE/DMC READER Qpix software platforms support barcode and QR code readers. Whether simply inserting header files (serial), managing the complete integration of reading devices for the automatic selection of templates, or calling up data from superordinate systems (optional) – barcode/QR code readers simplify work procedures for the tester, while also preventing operating errors.

BARCODE/QR CODE/DMC READER Qpix software platforms support barcode and QR code readers. Whether simply inserting header files (serial), managing the complete integration of reading devices for the automatic selection of templates, or calling up data from superordinate systems (optional) – barcode/QR code readers simplify work procedures for the tester, while also preventing operating errors. STRUCTURAL ANALYSIS MADE EASY QPIX INSPECT FOR MICROSCOPIC EVALUATIONS

The intuitive and user-friendly Qpix INSPECT software functionality provides a comprehensive toolbox for microscopic evaluations and result documentation. The multifunctional software can be customized for customer-specific measuring tasks and complemented with add-on modules.

INSPECT PARTICLE SIZE DETERMINATION Particle size determined according to DIN EN ISO 643 and ASTM E112 via linear or circular section method Results of the analysis provided as tables or diagrams Documentation of statistical characteristics of particle size and segment lengths cutting through the particles

INSPECT PARTICLE SIZE DETERMINATION Particle size determined according to DIN EN ISO 643 and ASTM E112 via linear or circular section method Results of the analysis provided as tables or diagrams Documentation of statistical characteristics of particle size and segment lengths cutting through the particles INDUSTRY 4.0 QCONNECT FOR CONNECTED TOMORROWS

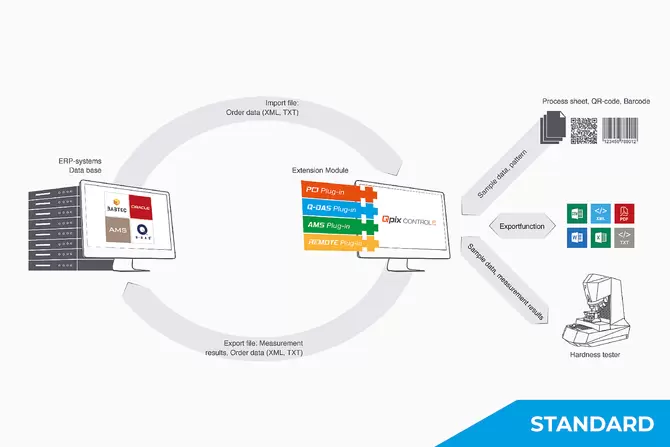

Qconnect is the interface in QATM Qpix Control2 software, providing customers with a full portfolio of inter-device connectivity - from serial production, open XML interfaces (bi-directional) and pre-specified plug-in solutions, such as the QDAS Plug-In+, through to customer-specific connectivity solutions implemented completely by QATM. We have a professional solution for every applicational requirement.

Available functionalities & formats:

REPORT, PRINT, PDF, XML IE, CSV, TXT, WORD, EXCEL, AUTO EXPORTER, MAIL, Q-DAS, AMS IE, IOT, LIMS, OPCUA, PCI IE (ERP, BABTEC, ORACLE, SAP)

APPROVED QUALITY CALIBRATION & MONITORING

CALIBRATION MANAGER This is a leap forward for calibration result management - The QATM Calibration Manager reminds operators of the necessary tests at freely definable intervals. Test results are added to the ongoing statistical record at the push of a button.

CALIBRATION MANAGER This is a leap forward for calibration result management - The QATM Calibration Manager reminds operators of the necessary tests at freely definable intervals. Test results are added to the ongoing statistical record at the push of a button. QNESS 10 / 60 A+ PARAMETRY

Hmotnost: 60 kg

Rozsah zkušební síly:

Qness 10 A+: 20 gf - 10 kgf (0.196 - 98.07 N)

Qness 60 A+: 0.25 gf - 62.5 kgf (0.00245 - 612.92 N)

Testovací metoda: Vickers, Knoop, Brinell, Rockwell (volitelné)

Testovací sekvence: Plně automatizovaná / elektronická aplikace síly

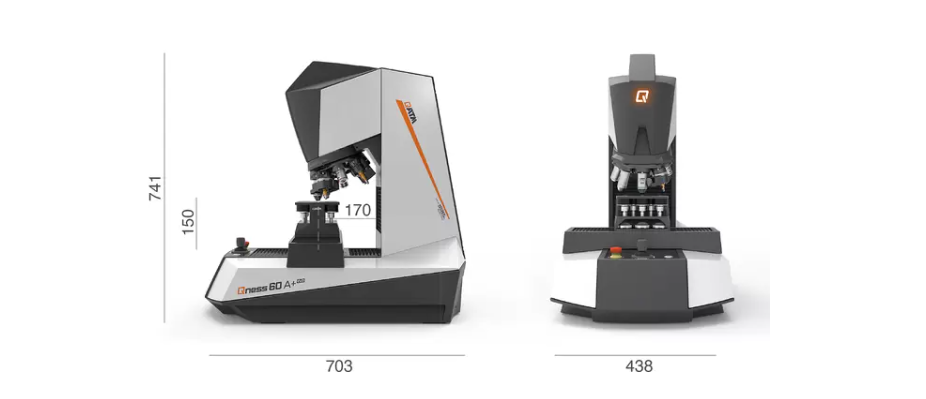

Z-axis: Dynamic, automated (CAS-Technic)

Z-axis travelling distance: 150 mm (5.91“); Option: 260 mm (10.2“)

Throat depth: 170 mm (6.69“)

Tool positions: 8-fold motorized tool changer max. 3 hardness testing modules, max. 7 lenses:

Camera system: 5 Mpixel - CMOS color, USB3.0

Optical system: Upright microscope with Koehler lighting

Aperture diaphragm: motorized

Lenses: XLED 2x, 2.5x, 5x, 10x, 20x, 50x, 100x

Lens types: Standard (Achromat) and High Quality (Semi-apochromat) for hardness testing and microscopy XLED for optimised Brinell hardness testing

Field of view (acc. to equipment): 0.074x0.055 mm (100x) to 2.80x2.10 mm (XLED 2)

Sample image camera: 5 Mpixel - CMOS color, USB3.0 52 x 39 mm (2.05 x 1.54“)

Test anvil / XY cross slide: Automatic cross slide

Table size: 150 x 120 mm (5.91 x 4.72“); Option 300 x 120 mm (11.8 x 4.72“)

Positioning accuracy: +/- 2 μm

Traverse path at cross slide: X 150, Y 150 mm (5.91 x 5.91“); Option: X 300 x Y 150 mm (11.8 x 5.91“)

Control elements: Emergency stop, Start button, Joystick X/Y/Z

Software: Qpix Control2

Max. workpiece weight: 50 kg (110 lbs)

Weight of basic device: 60 kg (132.3 lbs)

Included basic equipment: Indenter Vickers ASTM + DAkkS; Lens 5x, 20x, 50x

Interfaces: 1 x USB 3.0

Power supply: 100 – 240 V ~1/N/PE, 45-65 Hz

Brožury, videa

Video

Brinell/Knoop/Vickers Hardness Tester Qness 60 EVO

Související produkty

| Hmotnost | 60 kg |

| Rozsah zkušební síly | Qness 10 A+: 20 gf - 10 kgf (0.196 - 98.07 N) Qness 60 A+: 0.25 gf - 62.5 kgf (0.00245 - 612.92 N) |

| Testovací metoda | Vickers, Knoop, Brinell, Rockwell (volitelné) |

| Testovací sekvence | Plně automatizovaná / elektronická aplikace síly |

| Z-axis | Dynamic, automated (CAS-Technic) |

| Z-axis travelling distance | 150 mm (5.91“); Option: 260 mm (10.2“) |

| Throat depth | 170 mm (6.69“) |

| Tool positions | 8-fold motorized tool changer max. 3 hardness testing modules, max. 7 lenses |

| Camera system | 5 Mpixel - CMOS color, USB3.0 |

| Optical system | Upright microscope with Koehler lighting |

| Aperture diaphragm | motorized |

| Lenses | XLED 2x, 2.5x, 5x, 10x, 20x, 50x, 100x |

| Lens types | Standard (Achromat) and High Quality (Semi-apochromat) for hardness testing and microscopy XLED for optimised Brinell hardness testing |

| Field of view (acc. to equipment) | 0.074x0.055 mm (100x) to 2.80x2.10 mm (XLED 2) |

| Sample image camera | 5 Mpixel - CMOS color, USB3.0 52 x 39 mm (2.05 x 1.54“) |

| Test anvil / XY cross slide | Automatic cross slide |

| Table size | 150 x 120 mm (5.91 x 4.72“); Option 300 x 120 mm (11.8 x 4.72“) |

| Positioning accuracy | +/- 2 μm |

| Traverse path at cross slide | X 150, Y 150 mm (5.91 x 5.91“); Option: X 300 x Y 150 mm (11.8 x 5.91“) |

| Control elements | Emergency stop, Start button, Joystick X/Y/Z |

| Software | Qpix Control2 |

| Max. workpiece weight | 50 kg (110 lbs) |

| Weight of basic device | 60 kg (132.3 lbs) |

| Included basic equipment | Indenter Vickers ASTM + DAkkS; Lens 5x, 20x, 50x |

| Interfaces | 1 x USB 3.0 |

| Power supply | 100 – 240 V ~1/N/PE, 45-65 Hz |

Mikrotvrdoměry QNESS

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.