Popis

Qpix Control 2 - QATM (do roku 2019 QNESS) SOFTWARE

- Přístroj - specifický software

- Moderní a konzistentní softwarový design

- Inovativní 3D koncept ovládání

- Profesionální aplikace plně automatických zkušebních programu

- Komplexní správa dat

suitable for: Q10/30/60 A/A+, Q150 A/A+, Q250/750/3000 A/A+, Q250/750/3000 CA/CA+

Qpix Control2 heralds a new generation of hardness testing software. It has been developed based on customer input and feedback to guarantee maximum user-friendliness. New standards in hardness testing are now being established thanks to the controlled test head with automatic height adjustment and contact-free gauging, complete integration of the Qness sample holders, CAD compatibility with 3D component imaging and a wide variety of easily comprehensible 3D control elements and view angles within the software.

Innovative CAS technology (Collision Avoidance System) protects the mechanical components in the device from collisions and operating errors by generating 3D preview calculations of all movements in the visualized testing area.LOAD SAMPLES

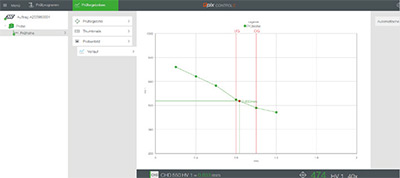

Predefinition of test programmes with a fixed number of test points. Can also be selected with manual slide, digital micrometre spindle and position-feedback

LOAD SAMPLES, LOAD ROW, START

3 STEPS TO THE RESULT

LOAD SAMPLES

|

The machine moves automatically to sample holder height. Image of sample is taken automatically. |

LOAD ROW

|

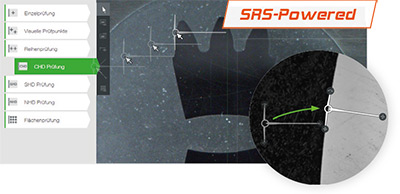

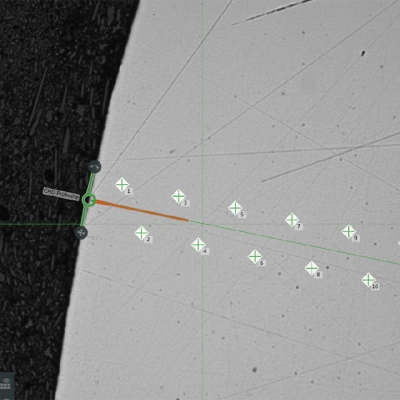

SRS - Speedy Row Set-up: Drag the row of test points to the desired position. The serial Auto-Snap function corrects the starting point of the test row automatically |

START TEST SEQUENCE

|

|

MULTIPLE SAMPLES, TEMPLATE, MANAGEMENT, OPTIMUM STOP,…

UNLIMITED POSSIBILITIES WITH A COMPREHENSIVE RANGE OF SERIAL FEATURES

MULTIPLE AND DIVERSE SAMPLES

|

Simple management of several samples at the same time even with a variety of sample types in a single mould. |

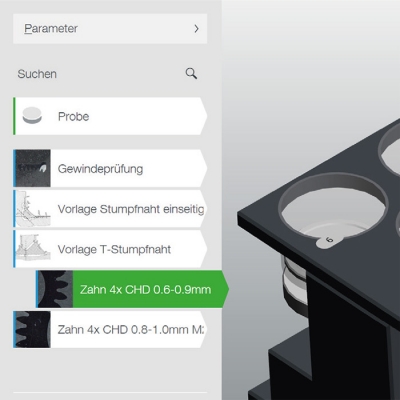

CLEARLY STRUCTURED TEMPLATE MANAGEMENT

|

Graphic presentation of stored templates with compre-hensively detailed descriptions and freely selectable guidelines. |

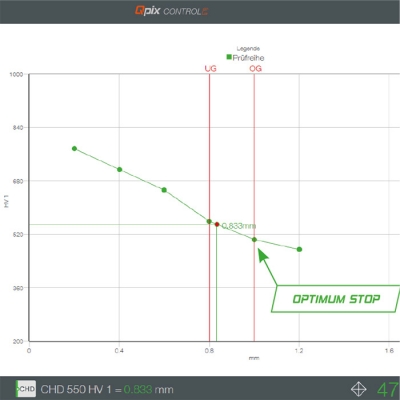

CHD/SHD/NHD WITH OPTIMUM STOP

|

Time-saving test mode ‘Complete all indentations - then evaluate’ and ‘Optimum Stop’ to complete test series as soon as the lower hardness limit has been undercut. |

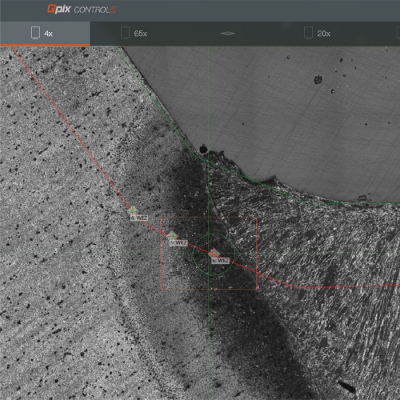

WELDING SAMPLE TOOLS

|

Points along - and parallel to - a polygon line, test point marking and guide circles for exact test point positioning in the heat affected zone of the welded sample. |

SINTER FUNCTIONS

|

Grouping of test points to gain averages and deletion of anomalies in hardness profiles. |

PREDICTIVE CALCULATION OF TEST POINTS

|

Displays the expected indentation size to simplify positi-oning and provides graphic warning when test points are closer than the normed minimum distance. |

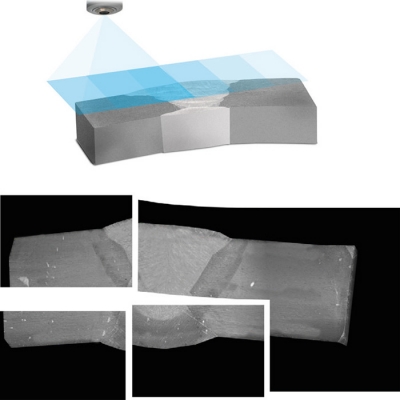

PANORAMA IMAGE FUNCTION

|

For sample image camera and measurement camera. Crystal clear sample images, from very small to extremely large test items. Automatic imaging can be programmed for before and after test sequence completion. |

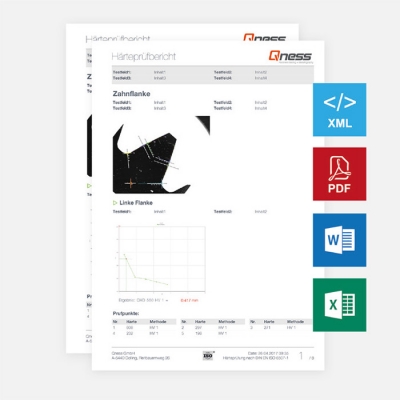

PROFESSIONAL DATA MANAGEMENT

|

Configurable protocol and data presentation. Wide range of structuration options for stored test item data. Adaptable content for export files and protocol content simplifies daily operation with Qpix Control2 software. |

ADVANCED TEST BLOCK MANAGEMENT

|

Redefining calibration result management: The Qness Calibration Manager can be set up to provide users with reminders of necessary checks at selected intervals. Test results can be added to the ongoing statistical profile at the push of a button. |

EDGE RECOGNITION, CONTOUR SCAN,…

INTELLIGENT OPTIONS

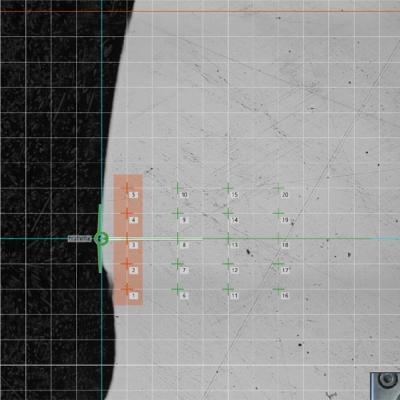

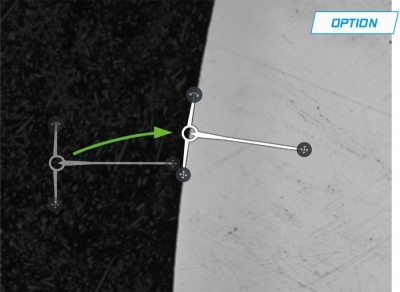

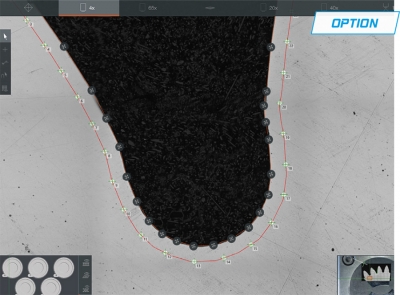

EDGE RECOGNITION

|

Working with program templates and the edge recognition software module makes fine-positioning of test rows irrelevant. The machine moves to the start points automatically and corrects their positions before the test sequence is started. |

CONTOUR SCAN

|

Users can choose whether to approach the entire section or a partial segment of a contour. The measurement lens scans the entire route and stores all data in the program. Subsequently, a chosen number of the test points can be programmed into the system, or at chosen distances, relative to the edge. This programming enables the hardness testing sequence to be conducted completely automatically. |

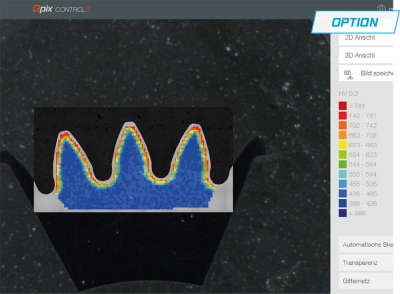

2D/3D MAPPING

|

Distribution of hardness across segments or entire surfaces of heat treated components. Coloured graphic representation in 2D and freely rotatable 3D views of the sample image. |

| Hmotnost | 0.1 kg |

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.