Popis

SCRETCHTESTER SMT-5000

Stolní model pro vrypové a indentační zkoušky

- Odolnost proti poškrábání

- Tvrdost a modul pružnosti

- Tření a opotřebení

- Inline 3D optické profilometry

ISO compliant instrumented Indentation and scratch tester. Patented, combined with an in-line 3D profilometer for comprehensive surface analysis.

POPIS PŘÍSTROJE:

- Unique combination of indentation, scratch, profilometer, film thickness testing on one automatic platform.

- Patented piezo and capacitive sensor technology.

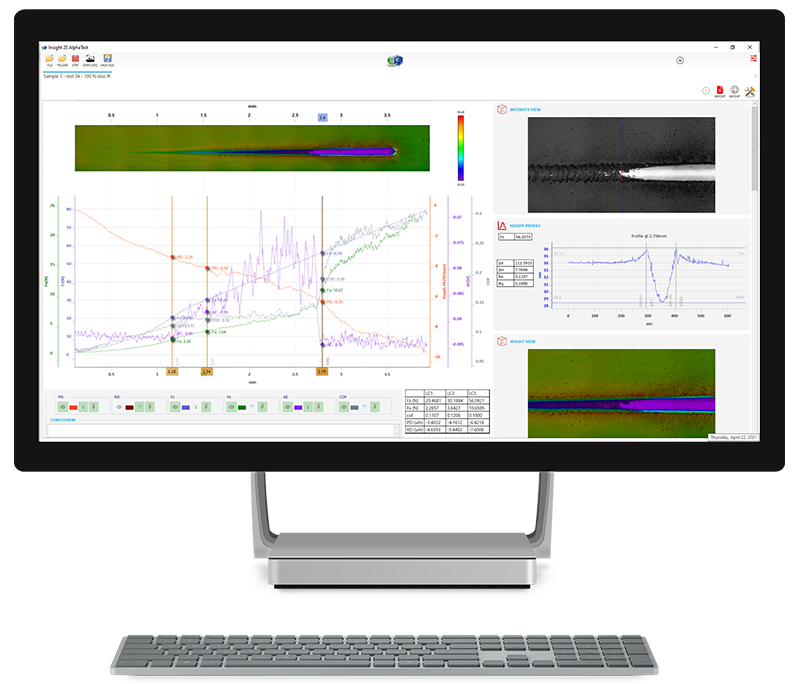

- Patented image correlation between scratch data and 3D images.

- Nano, micro indentation and scratch tests on same platform using fast exchange heads.

The Surface Mechanical Tester SMT-5000 is a versatile instrument. It merges the ability to measure mechanical properties, such as hardness, modulus, scratch adhesion, film thickness, in addition to surface roughness and many others. All this power is consolidated in one single platform. To that end, the IST module provides both indentation and scratch. Combining piezo actuation and capacitive sensing technologies, the IST brings the highest precision measurements from nano to micro ranges.

Besides the IST module, the SMT-5000 incorporates spectral reflectance film thickness with 3D profilometry and environmental modules. All these capacities cater to demanding engineers and researchers in many fields.

A SURFACE MATERIAL TESTER LIKE NO OTHER

Customize the SMT-5000 To Fit Your Needs

|

|

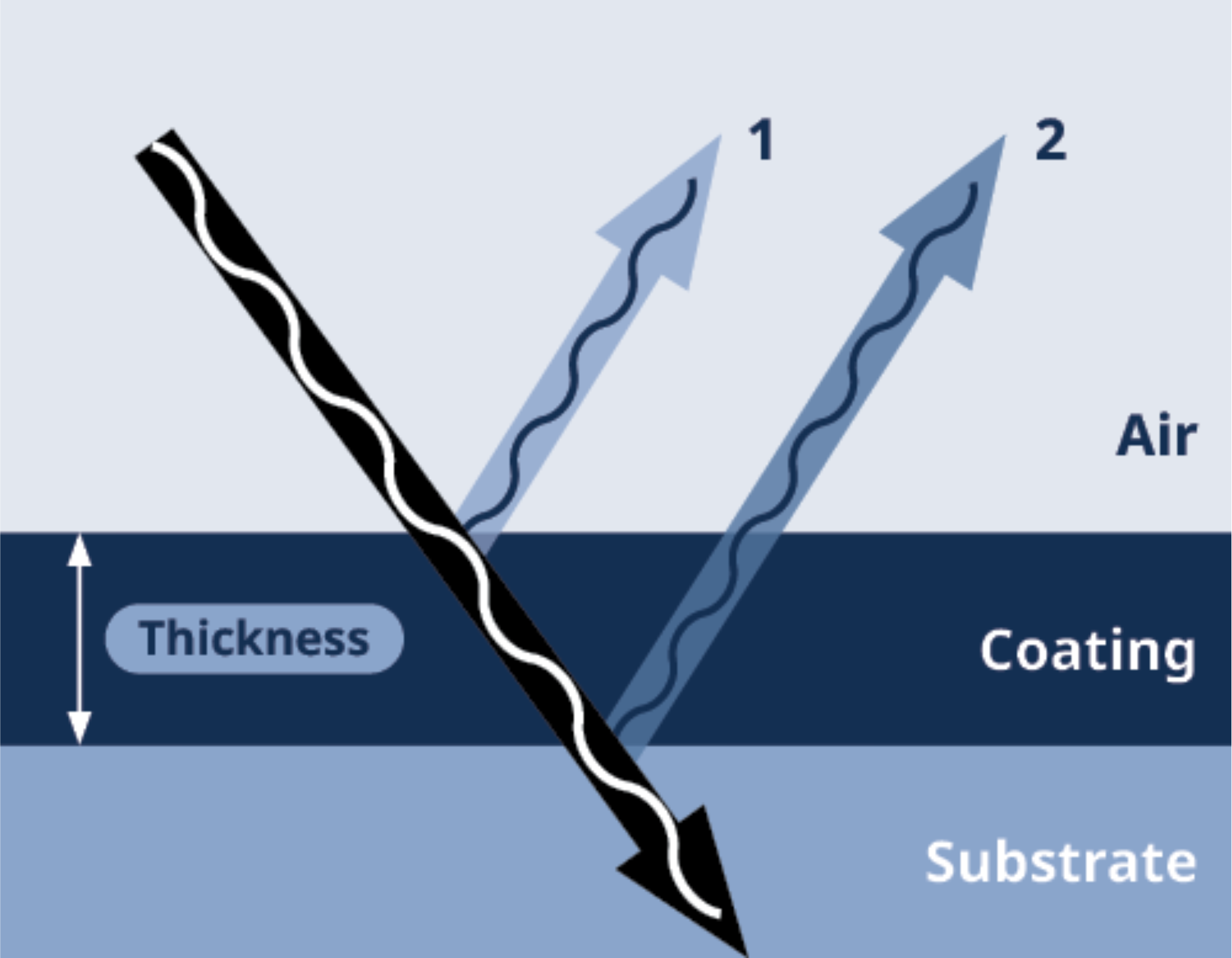

Based on spectroscopic reflectance, film thickness measurement (FT-100) module provides a super fast and direct non contact film measurement. High precision multiple Z drives with high resolution encoders to move testing and inspection modules.

Open platform architecture for superior modular testing and ease of use. |

|

|

|

|

The SMT-5000 Scratch Tester performs scratch tests in nano, mico and macro force ranges.

|

Take a closer looks at the SMT-5000’s micro indentation capabilities

|

Put it in action. The SMT-5000’s versatility fulfills all scratch applications.

|

Instrumented Indentation Tester

|

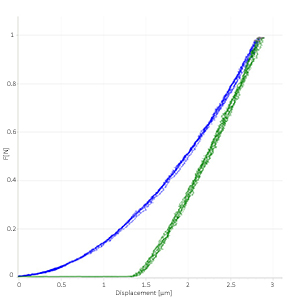

Automatic load and displacement curves, Hardness (Traditional and instrumented), Elastic Modulus, Creep, and many more calculations.

|

|

|

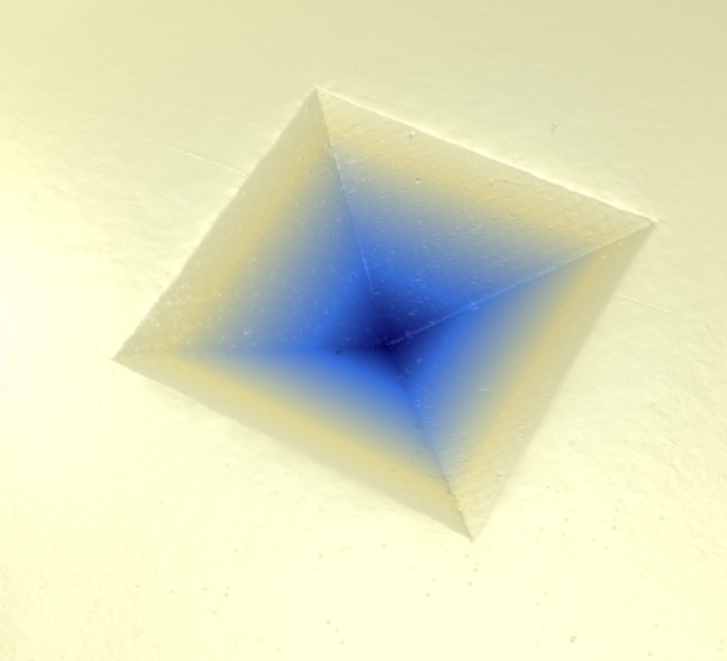

Characterize coating adhesion, scratch resistance, scratch hardness and more.

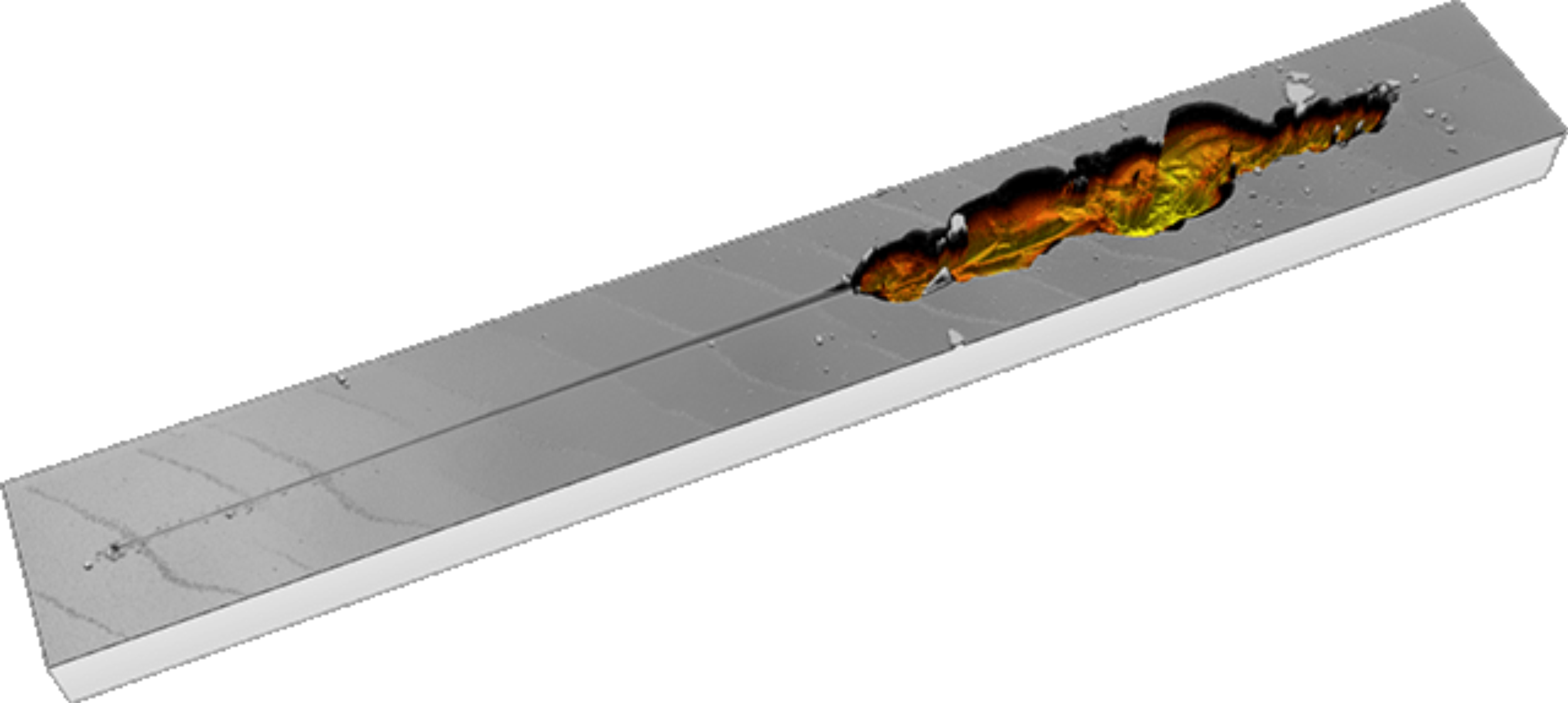

The synchronization of scratch data and 3D imaging ( Patent US 10,024,776 B2) is a unique and novel tool to study surface deformation and failures.

|

AUTOMATIC STICHING OF IN-LINE 3D IMAGE

|

The complete 3D image of the scratch is obtained via automatic post-test imaging. The critical loads are easily positioned on the 3D panorama. In addition to the critical loads, the typical measurements enabled by this 3D imaging include scratch volume, penetration, residual deformation, roughness, and volume wear. |

Load Profile and Custom Motions

Switch Quickly From Indenter to Scratch Tester

| Load Profiles: constant, linear or user defined load profiles. The applied normal force and resulting friction forces measured using precise NIST traceable sensors. |

Versatile XY Stage: The automatic XY stage allows to perform multiple scratch or indentation on single or multiple samples automatically. Tests can be customize to achieve any motion profile such as straight, curved, circle, zigzag, and more.

|

|

|

|

Indentation With Rockwell Tip |

Scratch With Cutting Tool |

Non Destructive Film Thickness Measurement

|

Ultra fast coating thickness determination

The film thickness measurement module uses spectral reflectance to obtain the thickness of a coated surfaces.

|

|

PATENTED INTEGRATED IN-LINE 3D PROFILOMETER

|

|

The profilometer is optimized to image scratch and indentation marks with high resolutions. Automatic multiple imaging modes selection to image any sample surface – transparent, glass, mirror, rough, smooth, steep slope, and much more with ease.

Allows detection of cracks at the surface with notable contrast

Allows high resolution images of flat surfaces

Measures steep slopes, transparent, dark or rough surfaces

2D profiles with high resolution and real colors |

Sensors and Chambers

Application specific solutionsEnvironmental chambers and a variety of sensors create numerous test variations that replicate real-life scenarios. |

|

|

C

Correlation of Deformation, Failure, and Surface Morphology Data

|

Automatic surface deformation assessment with the comparison of before and after 3D images of the surface.

Single or multiple scratches can be performed using predefined recipes. Cross profiles measurements are available anywhere along the scratch. A simple and customizable report is generated with 3D images correlated to scratch data. Moreover, each critical load is presented with separate zoomed images. Additionally, other measures such as friction, roughness, residual depth, volume wear and permanent deformation are also provided.

|

|

Brožura RTEC - kompletní nabídka přístrojů a aplikací (1.1 MB)

Brožura RTEC - kompletní nabídka přístrojů a aplikací (1.1 MB)

BROŽURA Multifunkční tribometr SMT-5000 (3.7 MB)

BROŽURA Multifunkční tribometr SMT-5000 (3.7 MB)

VIDEA:

| Hmotnost | 0.1 kg |

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.