Popis

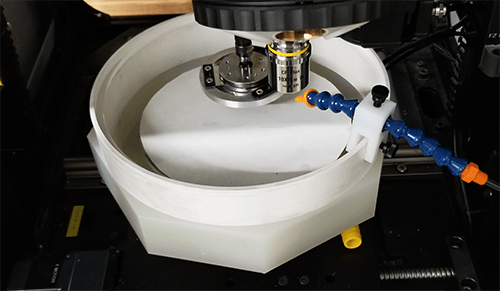

CMP TESTER CP-5000

R&D řízené leštění, efektivní vývoj procesů a testování leštících materiálů.

- Koeficient tření v reálném čase

- Integrovaný 3D profilometr

- Lze namontovat několik velikostí destiček

- Teplotní a akustická emise ke studiu procesu

POPIS PŘÍSTROJE:

|

|

Advance process and product development with our CMP R&D polisher. We optimized product development by providing several polishing processes on one platform. This includes a wide speed range, closed-loop downforce control, versatile wafer holders, and automatic slurry delivery system. Additionally, the CMP tester monitors several in-line signals during the polishing process. Besides polishing wafers & substrates, the tester comes with an in-line surface profilometer. This combination provides information on how the surface, friction, and wear changed. As well as, why imperfections occur.

CMP Tester Features

|

|

|

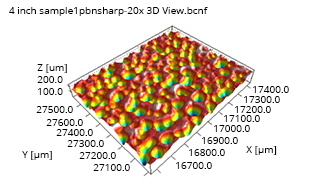

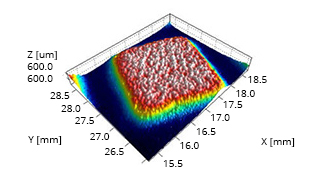

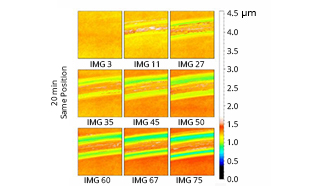

Patented Integrated In-line 3D Profilometer

Characterize pad surface with nm resolution. The profiler comes with confocal, interferometer, dark field, and bright field modes. The chemical mechanical polisher provides automatic stitching across large surface areas. Essential for volume wear and roughness calculations.

|

|

|

|

Pad 1

|

Pad 2

|

3D Surface Change

|

Brožura RTEC - kompletní nabídka přístrojů a aplikací (1.1 MB)

Brožura RTEC - kompletní nabídka přístrojů a aplikací (1.1 MB)

VIDEA:

| Hmotnost | 0.1 kg |

Buďte první, kdo napíše příspěvek k této položce.

Pouze registrovaní uživatelé mohou vkládat příspěvky. Prosím přihlaste se nebo se registrujte.